PRODUCTION SCHEDULER

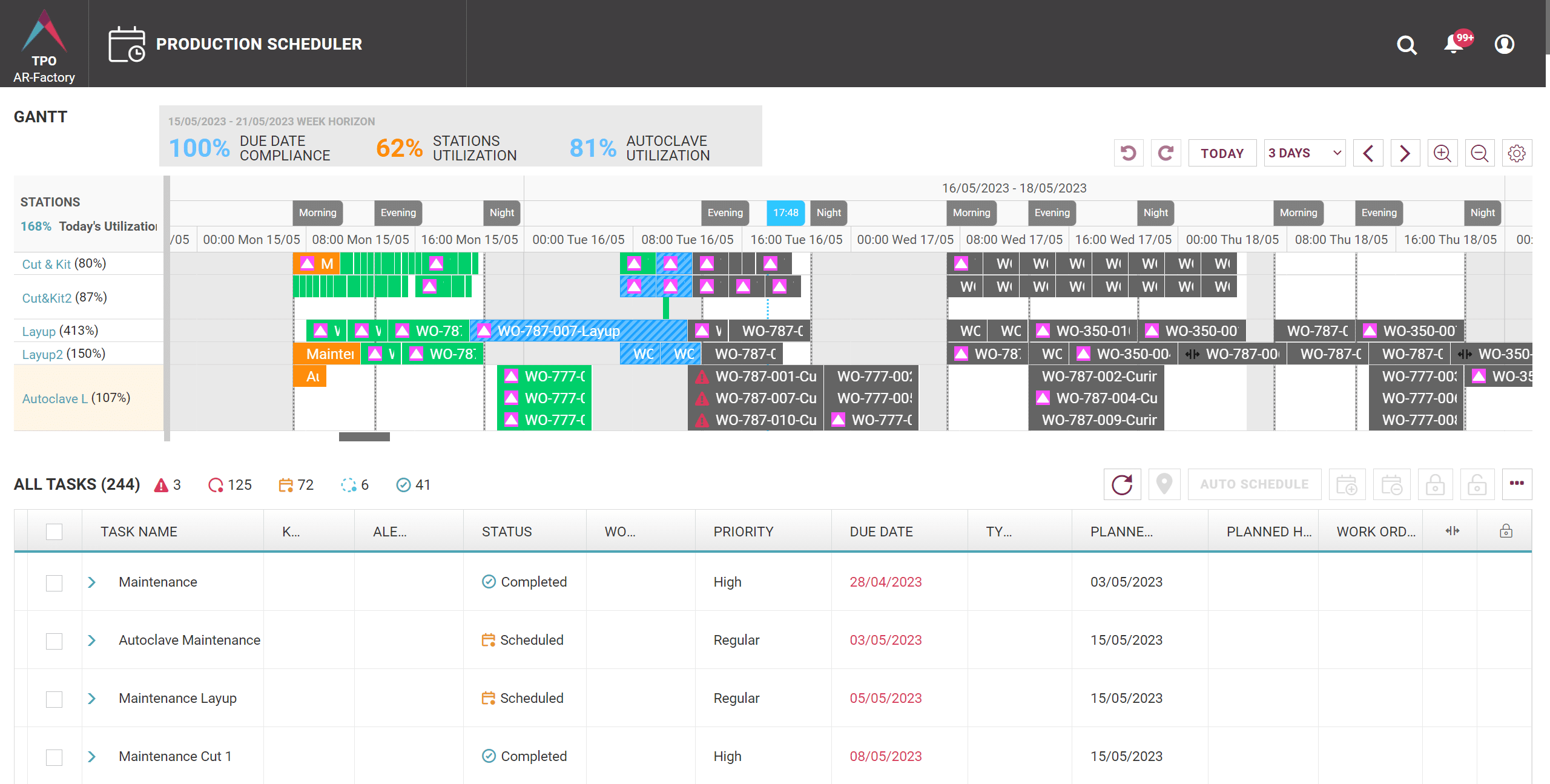

The production scheduler application uses AI-based algorithms to automatically create & optimize plans to maximize the use of your factory floor resources & ensure on time delivery, considering variable demand and available resources like machines, material and tools.

Play Video

HOW DOES IT WORK?

A powerful scheduling application, quickly responds to dynamic changes on the factory floor, using advanced AI algorithms to maximize production throughput and minimize inefficiencies.

Tracks production progress

Compares planned vs. actual

Improves sustainability goals

Connects planning and operations

Why can Plataine's Scheduler help you grow?

- Improve factory throughput

- Ensure on-time delivery

- Reduce energy waste

- Achieve sustainability standards

New Autoclave Scheduler Drives Sustainability

Save power & reduce autoclave operation costs

Increase autoclave efficiency & release bottlenecks

Increase overall factory throughput and efficiency

Your schedule is always optimized & up to date

Upon any change on the factory floor, the highly responsive algorithm re-adjusts and re-assigns the tasks to keep the schedule valid ,optimized and up to date.

You can benefit from:

100% visibility

95% time savings on optimized planning

15% work orders execution increase

SOLUTION BENEFITS

Access anytime, from any browser

Achieve your Production KPIs

Easy to use, intuitive UX & Gantt

Dynamic AI-based scheduling

React to unexpected events in real-time

Easy implementation & integration

CUSTOMERS ARE SAYING

"Together with Plataine, we set the best possible processes in place, allowing us to gain full

visibility and traceability over material and improve our overall efficiency."

Mr. Thierry DucroHead of Procurement and Supply Chain at Airbus-Hafei Read More

“We selected Plataine to reduce errors and material waste to zero. The software automates the material flow between our freezers and clean rooms, ensuring on-time delivery.”

Uri OrbachLight & Strong, CEORead More

“In addition to a highly impressive reduction in material waste, Plataine’s technology will bring us to a high level of process automation, leading to higher efficiencies."

Gourish Dabolkar,Kineco Kaman, Manufacturing Project Leader Read More

"For CTC, Industry 4.0 is within the framework of strategic and digital change. Together with Plataine, we help advanced manufacturers to scale and test new opportunities."

Marc FetteCTC CEO Read More

“I am confident that Plataine’s solution allows us the agility needed to adapt and thrive in times of unexpected crisis, such as the one we are living through today.”

Carlos Alberto DaluzCEO of Alestis do Brasil Read More

“We selected Plataine thanks to their strong track record in the wind industry. Plataine’s solution offered us immediate benefits by improving efficiency and flexibility."

Johannes KannenbergResponsible for the component rotor blade at ENERCON CTC CEO Read More

We started to see benefits from better yields and better understanding of our inventory as soon as we launched Plataine, with a 5% increase in our material usage efficiency.”

Mitchell SmithMRAS Composite Technology and Sustainability Leader Read More

“Plataine saves valuable time and reduces quality risks. We have managed to significantly increase our buy-to-fly ratio and improve our overall equipment efficiency.”

Shachar FineEVP Business Development at Kanfit Read More

Working with Plataine dovetails with our vision, enabling us to continue looking toward the future of advanced manufacturing and inspiring the leaders of tomorrow.”

Dr. Waruna SeneviratneDirector of NIAR ATLAS Read More

“Plataine’s solution resulted in improved material utilization and efficiency, leading to a significant reduction in costs, as well as increased production flexibility.”

Jens RewersCEO of RewAir Read More

Previous

Next