MATERIAL & ASSET TRACKer

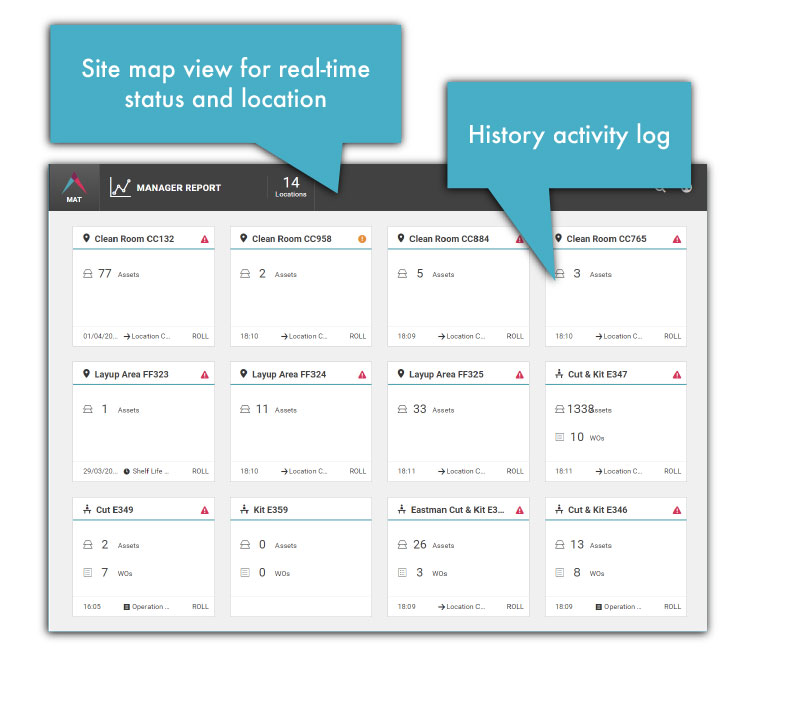

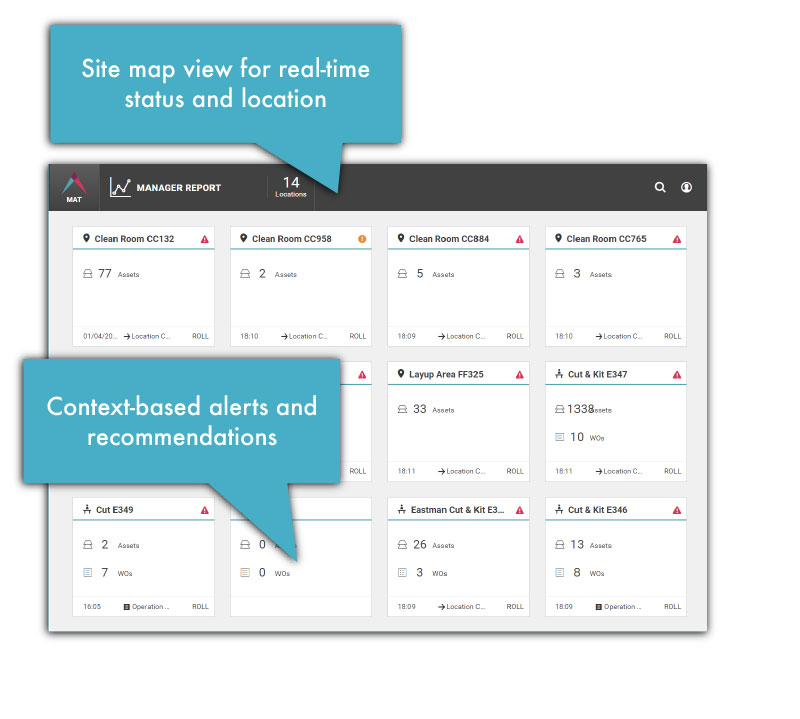

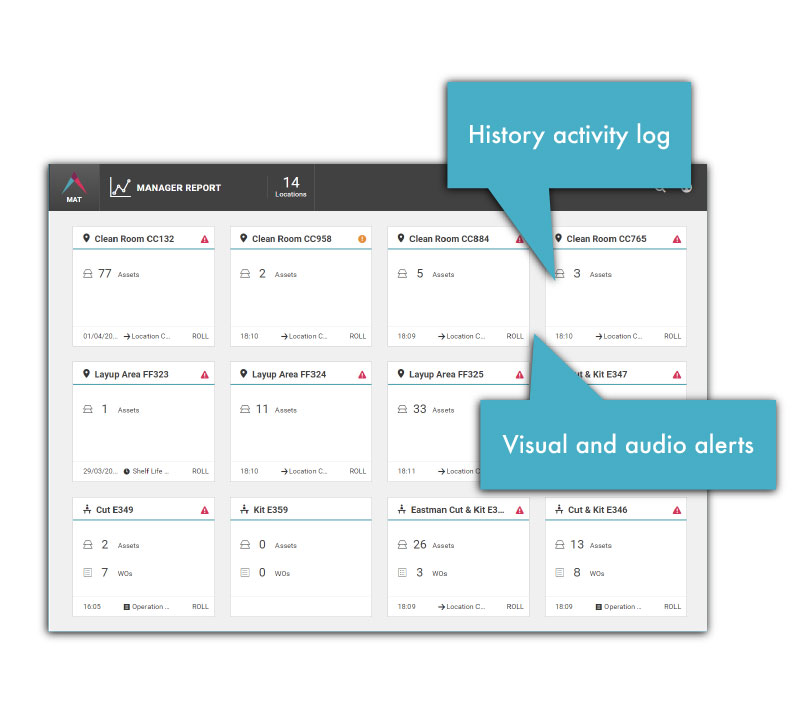

Material & Asset Tracker (MAT) uses IIoT technologies to collect information about material, equipment and operations and transform it into real-time context-driven recommendations and actions.

Eliminate errors and save costs. Automation allows data to be sent from one part of the system to another leaving no room for errors.

Our solution digitally integrates with factory floor sensors to track & trace critical assets’ location, condition & status in real time.

All information is automatically logged, eliminating the need for manual reporting & paperwork.

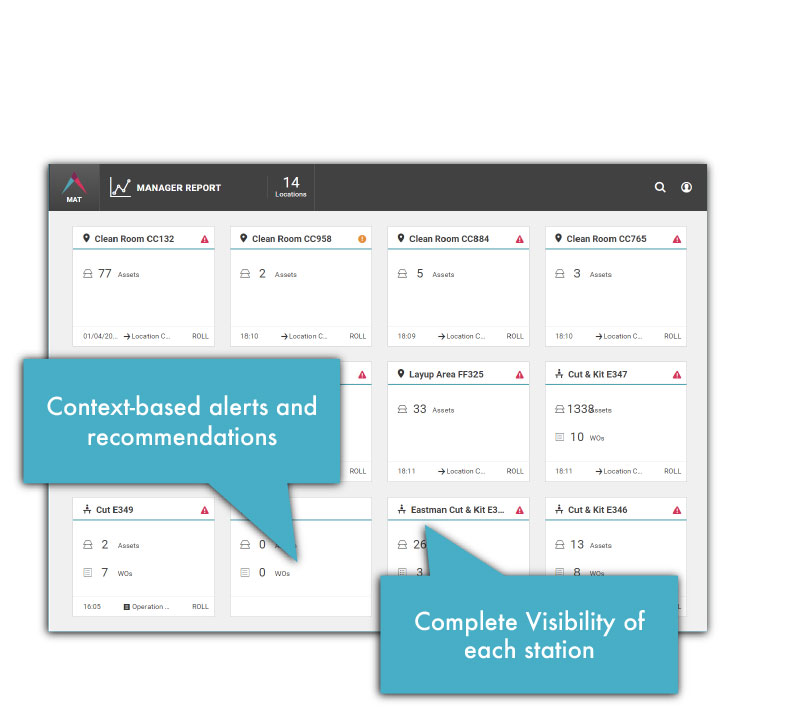

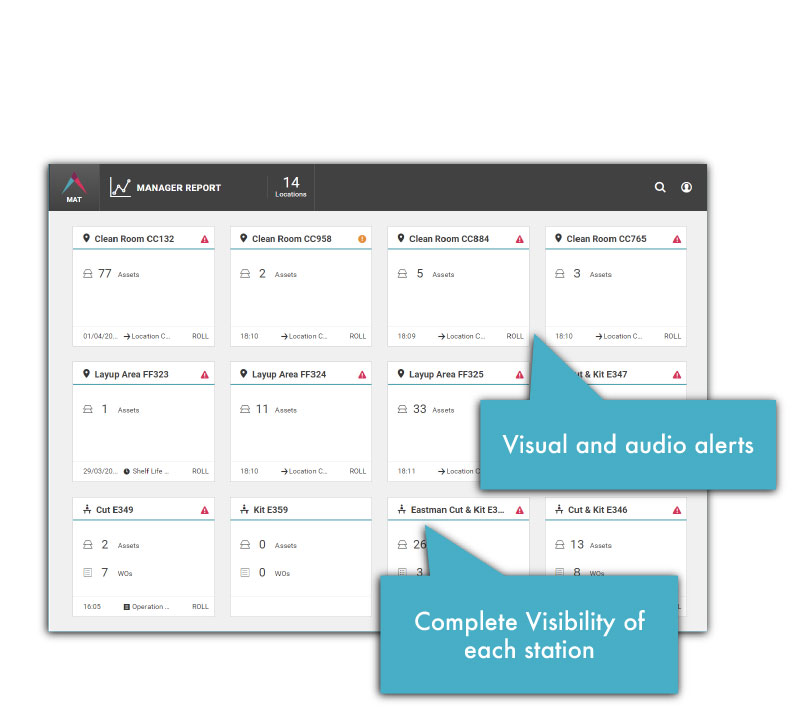

The system provides configurable alerts and context-driven recommendations using Big data analysis, driving efficiency, while reducing rework and waste.

Eliminate delays &

increase throughput

Digitize production &

eliminate paper work

Improve quality,

reduced re-work & waste

Be smart about your assets

The Material & Asset Tracker application puts every aspect of production at your fingertips in real time, allowing you to be more competitive by increasing material utilization, improving productivity and using AI for quality assurance, while increasing manufacturing throughput.

CUSTOMERS ARE SAYING