Case Study

MRAS – ST Engineering

Achieved 96% first-time-right yield for composite Nacelle structures

Overview

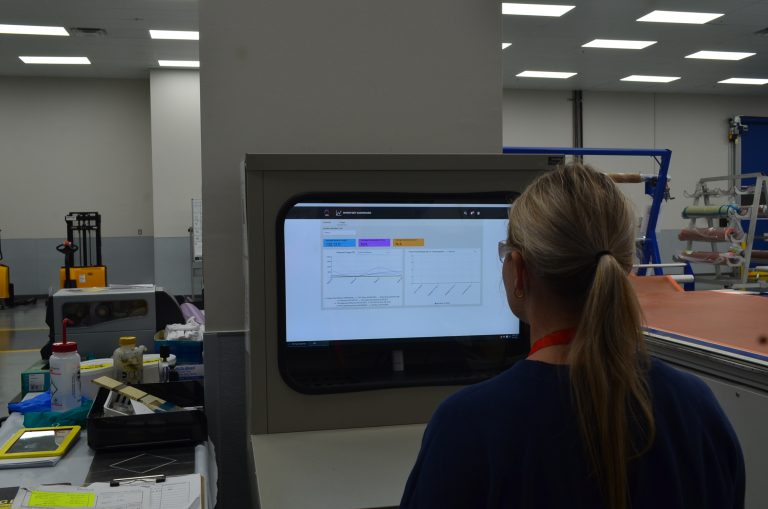

MRAS (an ST engineering company) decided to re-establish its in-house cutting and kitting operations, it wanted to drive the most efficient process

as possible. The goal was to create optimized cutting plans, to

reduce costs, eliminate material waste and digitize the process

from raw materials through the final product.

Learn how they did it!

Some of the achieved results:

- 95% elimination of out time excursion defects

- Achieved 96% first-time-right yield

- 7% Cost reductions for cutting and kitting operations

Read the case study to learn how MRAS automated their composite production processes