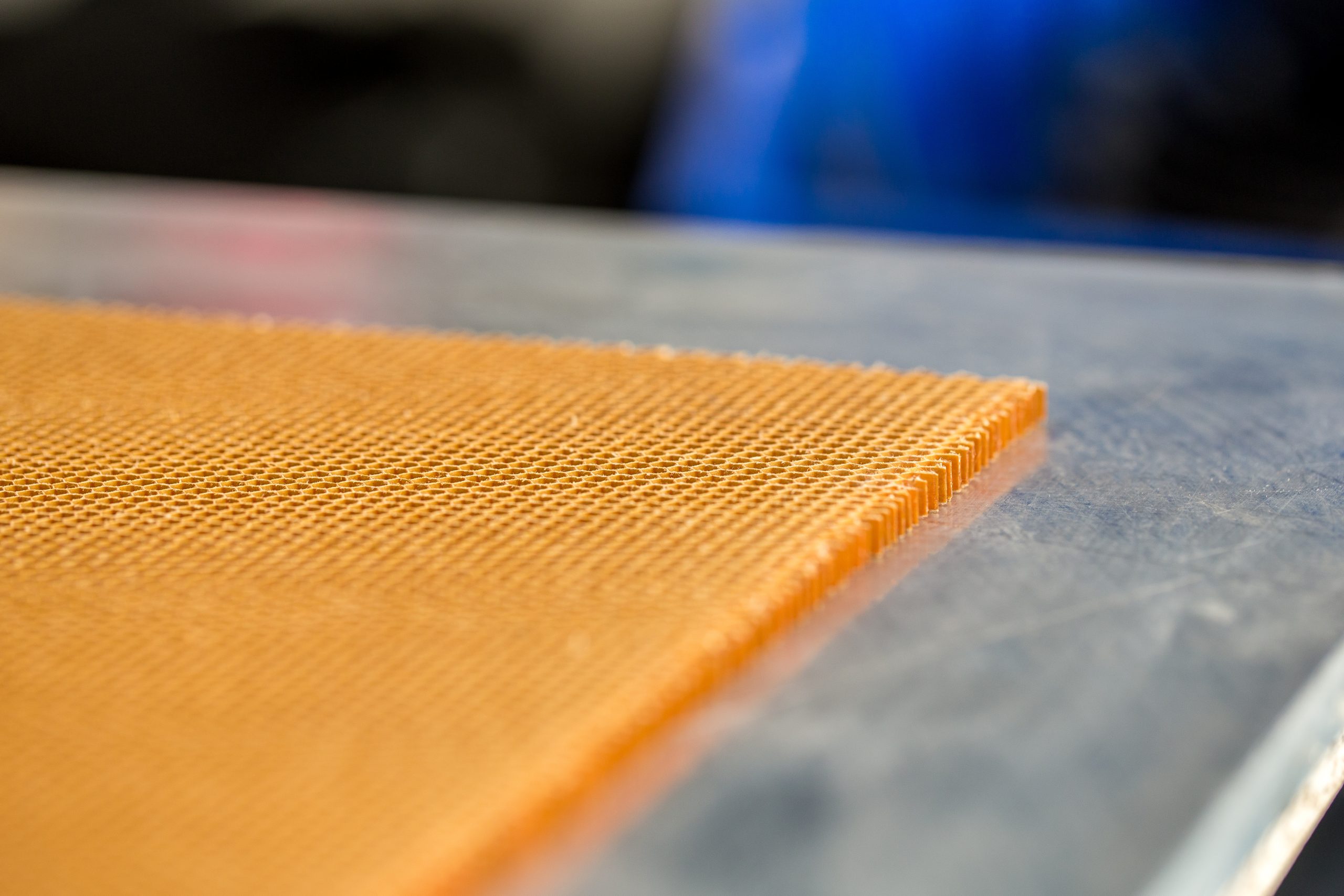

Honeycomb optimizer

Enabling flexible and easy work orders programming as well as automatically generating optimal cut plans resulting in significant material savings and reduced order-to-delivery time.

HoneycombOptimizer automatically considers two-sided cutting for laminated honeycomb (sheet flipping during the cutting process) and optimizes inventory management including use of remnants, as well as reducing time on machine set-up and tool changing. Plataine’s software has full visibility of the production floor’s overall performance, eliminates errors and drives process standardization to reach operational excellence.

HoneycombOptimizer increases factory material utilization while keeping an easy kitting process. Each kit is nested on its own, and the next kit begins right after the first one ends, ensuring an effective remnant strategy. An advanced learning algorithm runs each kit numerous times, ensuring quick run time.

Highly efficient nesting algorithm resulting in fast

and measurable ROI

Optimized inventory management with effective remnant strategy

Full visibility of the production floor’s overall performance, eliminates errors

up to 20% material savings

HoneycombOptimizer has a dynamic and highly efficient nesting algorithm, resulting in high material utilization, improved throughput, enhanced quality control, and fast and measurable ROI. The solution enables flexible and easy processing of work orders as well as automatically generating optimal cut plans resulting in significant improved material utilization.

CUSTOMERS ARE SAYING

READ THE FULL CASE STUDY

READ THE FULL CASE STUDY