Supplier Connectivity Manager boosts operational efficiency and supply chain collaboration by streamlining operations across OEM, suppliers, material suppliers and customers.

This Sustainability Conference will delve into the latest advancements in digital design tools, simulation, process optimization, and smart manufacturing applied to composites.

Middle River Aerostructure Systems implemented Plataine’s optimization solution, leading to optimized sustainability and operation processes.

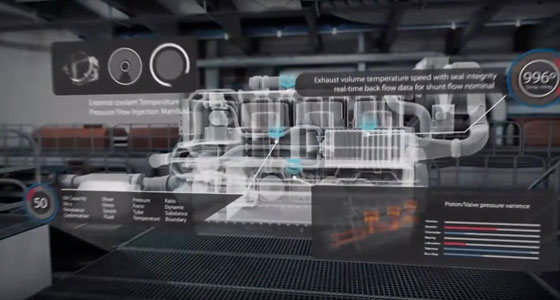

Lets take a closer look at the Digital Twin for manufacturing and explore the benefits, and actionable insights.

Plataine complements your ERP by optimizing and automating the production processes from material receiving to product shipping. It allows you to achieve growth because it is developed with manufacturers for manufacturers.

Kanfit, a leading aerospace manufacturer, digitized and optimized their operations by automating and streamlining time-sensitive material management, Optimizing cutting and kitting operations, reducing waste and production delays, which led to material utilization by up to 3%.

FabricOptimizer optimizes your Cut & Kit operations and integrates with your existing systems to enable automation and human-machine collaboration. FabricOptimizer Selects the best material roll (including remnants – short rolls).

President and CEO of Plataine, Avner Ben-Bassat, joined Ryan on the podcast to discuss industrial IoT and the current landscape of industry 4.0.

WoodOptimizer integrates with your existing systems to enable automation and human-machine collaboration. Automatically handling work orders, optimally creating cut paths for them according to preset machine configurations and creating a G-Code with minimal human interaction.

Tool Manager allows for automatic real-time tracking of tool location and usage, offering AI-based alerts on misplaced tools and predictive maintenance due with audio visual support.

Light & Strong, a manufacturer of advanced composite parts for the aerospace and defense industry, deployed Plataine’s AI and IIoT based software to optimize and automate its operations. The new solution will deliver significant reductions in material waste, as well as improved quality assurance and faster production times.

AI-Based Production Scheduling and IIoT Drive Advanced Manufacturing Agility in the New Normal, presented at SAMPE neXus 2021 by Amir Ben-Assa.

Work In Process (WIP) tracks all aspects of work advancement and process completion, providing visibility, real-time status, insights and AI-based recommendations.

Freezer Management Software tracks materials that are time and temperature sensitive, such as composites pre-pregs and resins, throughout production, ensuring higher quality while avoiding re-work and waste of composites prepreg materials.

Unpredicted changes on the shop-floor? No worries. Plataine’s production scheduler application will automatically create & optimize your plans.

A joint presentation by Plataine and Virtek, discussing opportunities for composites manufacturers using AI-based solutions

Watch this session to learn how AI can improve manufacturing production and boost industrial corporations, productivity and profitability and how these contributions can be measured, ROI wise.

Renault F1 Team has announced the implementation of Plataine’s IIoT solution to automate its composites manufacturing processes, leading to improved material utilization, full digital traceability and faster time-to-part, as part of its Industry 4.0 Digital Transformation Strategy.

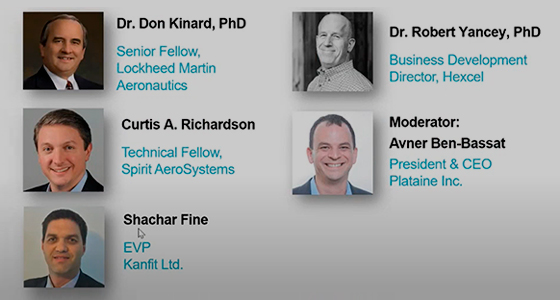

Plataine CEO, Avner Ben-Bassat, led an experts panel, exploring how Industry 4.0 is applied and impacting aerospace manufacturing, at all levels of the supply chain.

Our manufacturing optimization software constantly collects data from factory-floor sensors, tracking all tools and material and providing complete traceability of the Digital Thread, from raw material to end product. Plataine’s solution digitizes your factory and empowers your staff to make optimized decisions every time.

The ‘Cost of Poor Quality‘ [CoPQ] consistently comes up as one of the key issues manufacturers are tackling, and manufacturing optimization software that feeds off factory-floor sensors, helps prevent production delays and ensures quality.

Watch Plataine’s CEO Avner Ben-Bassat’s presentation from JEC World 2019 on ‘Implementing Artificial Intelligence in Composites Manufacturing: Opportunities, Challenges & Best Practices’

Smart Manufacturing, Industry 4.0, Big Data, new and old capital equipment — this panel utilizes fresh survey data and covers harmonizing new technology for the manufacturing environment as well as cost-effective modifications for practical affordable implementations of Industry 4.0 / Smart Manufacturing.

Google Cloud and Plataine combine top AI methods & machine learning technologies. In this session, we will demo how Google’s DialogFlow™ and Google Glass are incorporated into Plataine’s smart factory solutions offering operators and managers innovative communication methods with advanced digital assistants.

CEO Avner Ben-Bassat comments on the company’s value propositions with IoT and AI such as Digital Assistants on the production floor, guiding production floor staff through daily operations with alerts and notifications. Plataine works heavily in the industrial sectors such as Aerospace markets.

President & CEO, Avner Ben Bassat talking about Artificial Intelligence, Digital Traceability of Material & Assets. Manufacturing in the fields of aviation, wind energy, automotive, and heavy industry is complex and challenging, and factory leaders are constantly looking for hard ROI.

works with clients across these sectors to transform manufacturing facilities using solutions powered by Predix, the operating system for the Industrial Internet. Plataine helps companies capture and analyze data to provide specific recommendations to decision makers so they can take proactive action.

CEO Avner Ben-Bassat comments on the company’s value propositions with IoT and AI such as Digital Assistants on the production floor, guiding production floor staff through daily operations with alerts and notifications. Plataine works heavily in the industrial sectors such as Aerospace markets. Avner highlights how Aerospace uses raw materials and the sensitive nature of these materials, and the value of alerts related to expiring composites and how to use the supplies in an optimal manner.

CAMX 2017- Avner Ben-Bassat in panel discussion on the Internet of things and the digital thread in Composite part manufacturing

IoT, AI and Cloud-Computing in the Service of Composites Part Fabrication

With the rapid expansion of connected devices and sensors in composites component manufacturing processes, the sheer volume of data being collected dramatically increases.

Manufacturing optimization technology, utilizing AI, can collect IIoT-based data, analyze data trends, raise alerts and recommend – or even independently take – optimal actions, weaving a digital thread from raw material to the end-product, to guarantee highest levels of quality and quality control.

Industrial IoT and the Digital Twin: As companies grapple with ways to effectively deploy and scale new technologies that leverage industrial connectivity, clear pathways are emerging for the creation value from the massive amounts of data produced on the shop floor.

Panelists:

• Avner Ben-Bassat, President & CEO, Plataine Technologies

• David Riemer, VP, Aerospace and Defense Strategy, Siemens Product Lifecycle Management Software Inc.

• Jeff Smith, Director, Ideas Lab, Dassault Systèmes

Moderator: Greg Harris, PhD, PE, Associate Professor, Industrial & Systems Engineering; Director, Southern Alliance for Advanced Vehicle Manufacturing Center, Auburn University