INDUSTRIAL IOT

Integrating Intelligent, context-aware Industrial IoT software, represents dramatic opportunities for the smart factory as new sensor technologies collect vast amounts of data in real time, enabling to achieve high quality and cost reductions, while remaining competitive.

Industrial IoT Solution Benefits

- Smart manufacturing IoT based technologies & shop floor sensors collect production and quality data in real-time allowing you to see the big picture.

- Paperless production and increased manufacturing throughput driven by our Intelligent Automation software.

- Improved quality & quality control is achieved by maintaining full traceability of the Digital Thread from raw material to end product.

- Reduced re-work & waste due to our Artificial Intelligence algorithms and award-winning optimizers.

Smart, Connected Factory

Smart, connected factory provides the ability to remotely monitor, manage and analyze the data from the factory floor. Plataine’s Industrial IoT software uses sensors to collect vast amounts of data in real-time, starting from material receiving stage and all the way through the stage of the production process. This creates a rich Digital Thread, documenting the entire life cycle of each product, helping manufacturers meet the strict quality requirements and being audit-ready at all times while remaining profitable and competitive

Actionable Insights

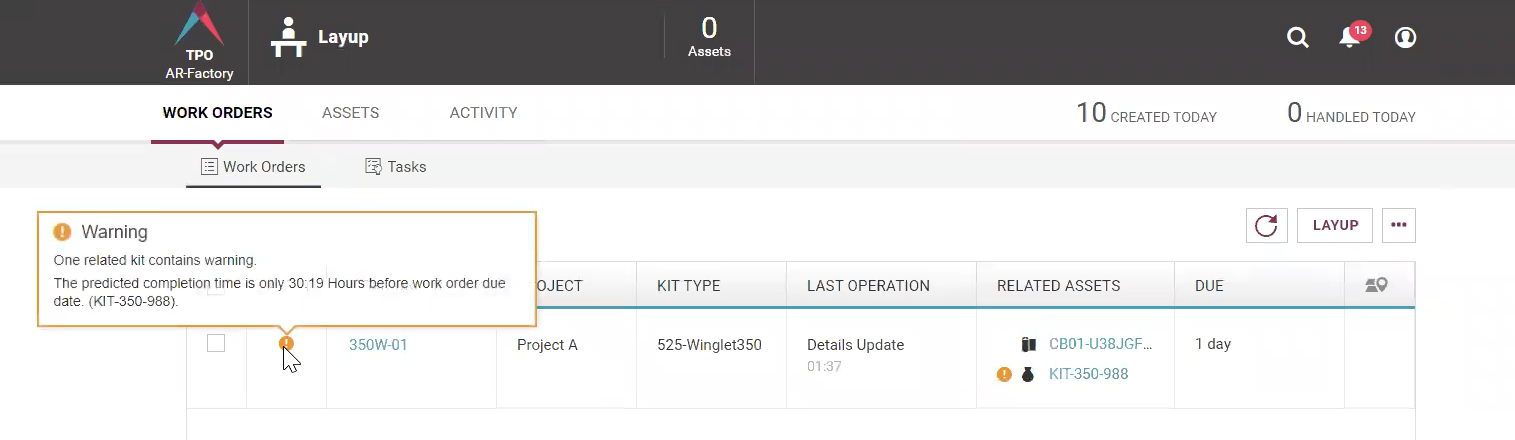

AI algorithms turn connected sensors that monitor asset’s location and condition into actionable insights: analyzing the root cause of quality issues, recuts, work interruptions & defective parts, improving quality and quality control. The result is manufacturing intelligence that generates accurate predictions, alerts on production floor issues, and helps to run the business much more efficiently, while minimizing production delays.

Plataine’s IIoT Software

Access anytime from any browser

Achieve you Production KPIs

Interactive Gant visualization

Easy to use, intuitive UX

Dynamic AI-based scheduling

Integrated with floor operations

Ease of implementation and integration

Remote deployment with zero downtime

Manufacturing process optimization

Manufacturing Process Optimization is the ongoing task of observing, developing, and implementing improvement strategies to manufacturing processes to do just that: minimize cost and maximize production. Monitor manufacturing processes and machinery in real time and identify what’s causing production bottlenecks. Analytics-driven visualizations of operational KPIs help you see, decide and act faster. By creating a “digital twin”—a digital representation of a physical asset—you can remotely monitor a machine’s status at any time.

Predictive tool maintenance

Predictive maintenance monitors the performance and condition of equipment during normal operation. It allows manufacturers to monitor their machine’s performance and plan maintenance and repairs ahead of time, to reduce the likelihood of failures and production of defected products. Predictive maintenance data also helps businesses to improve their product quality by ensuring machines and tools are being serviced on time.