In today’s rapidly evolving manufacturing landscape, staying ahead of the competition requires embracing digital transformation and adopting innovative technologies. One such transformative concept that is revolutionizing the manufacturing industry is the digital thread. The digital thread represents a connected ecosystem of data that flows seamlessly throughout the entire manufacturing process, enabling real-time insights and informed decision-making. In this article, we will explore the importance of the digital thread in modern manufacturing, steps to consider for its implementation, the technologies that enable its success, the benefits it offers, and the significance of building cross-functional teams for successful implementation.

Understanding the Importance of the Digital Thread in Modern Manufacturing:

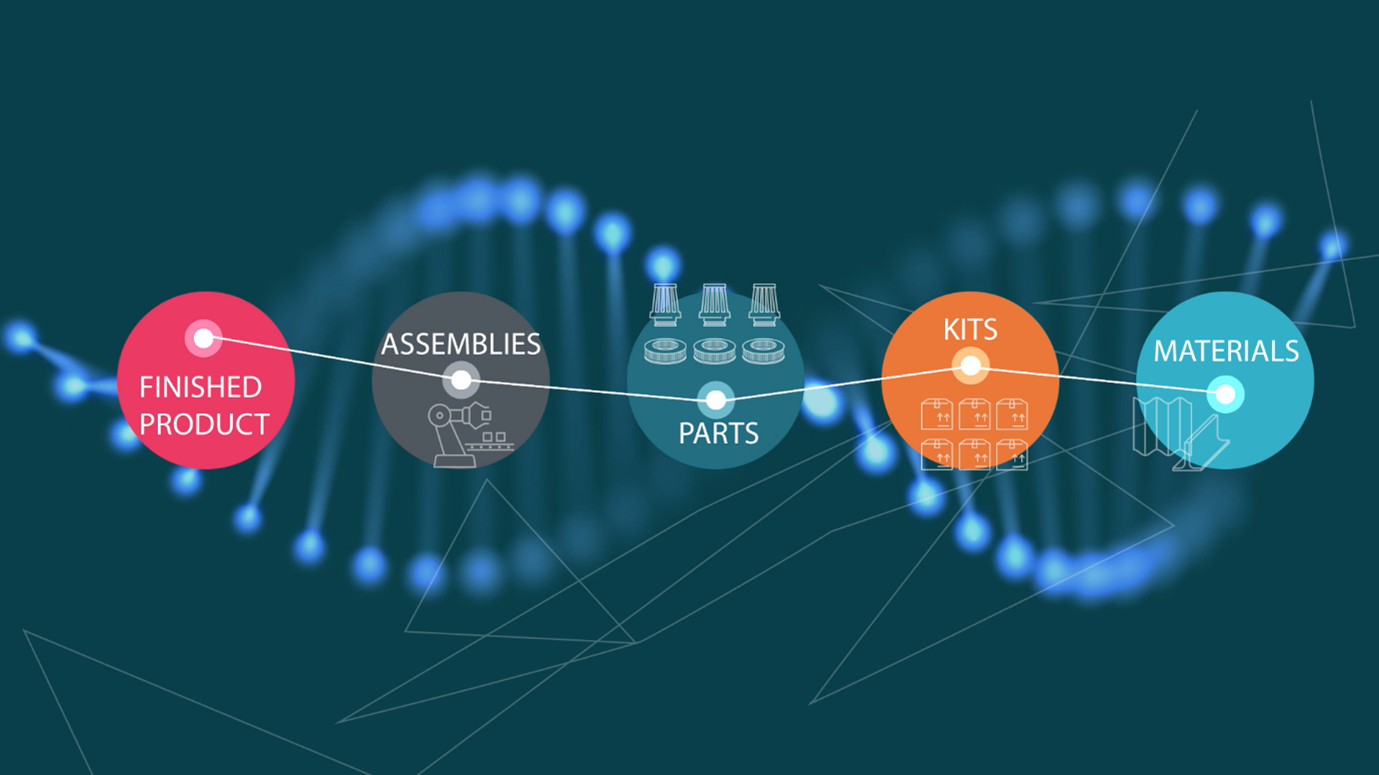

The digital thread in manufacturing refers to the continuous flow of data and information across different stages of the product lifecycle, from design and engineering to production, supply chain, and maintenance. By integrating various systems, processes, and stakeholders, the digital thread ensures that valuable data is captured, analyzed, and utilized throughout the entire manufacturing journey. This interconnectedness enables manufacturers to make data-driven decisions, optimize processes, improve quality, enhance traceability, and drive innovation.

How to Implement the Digital Thread: Steps to Consider:

Implementing the digital thread in manufacturing requires careful planning and execution. Here are the steps to consider:

- Define the scope and objectives: Clearly outline the goals and objectives of implementing the digital thread in your manufacturing processes. Identify specific areas where the digital thread can bring the most significant benefits, such as product design, production, supply chain, or maintenance. Set measurable targets to track progress and success.

- Assess existing systems and infrastructure: Evaluate your current systems, processes, and technologies to identify gaps and potential areas of improvement. Determine the necessary upgrades or investments needed to enable seamless data flow and integration across different stages of the product lifecycle.

- Establish data standards and governance: Define standardized data formats, protocols, and governance policies to ensure data consistency, integrity, and security throughout the digital thread. This step is crucial for interoperability and effective data utilization across various systems and stakeholders. Consider industry standards and best practices in data management.

- Select the right digital thread software: Choose a robust digital thread software solution that aligns with your specific manufacturing needs. Look for features such as data integration capabilities, analytics tools, visualization options, and collaboration functionalities. Consider factors like scalability, compatibility with existing systems, and ease of use for seamless implementation.

- Implement data collection and connectivity: Set up the necessary infrastructure to collect real-time data from machines, sensors, products, and processes. This often involves deploying IoT devices and sensors throughout the manufacturing environment. Establish reliable connectivity to transmit data to a centralized system for analysis and utilization.

- Integrate and analyze data: Ensure that data from various sources and systems can be integrated and analyzed in a unified manner. Implement data integration mechanisms that allow for seamless data flow across different stages of the product lifecycle. Utilize AI and analytics tools to derive meaningful insights from the collected data, enabling predictive maintenance, quality control, process optimization, and informed decision-making.

- Enable collaboration and communication: Establish platforms and tools that facilitate collaboration and communication among different stakeholders involved in the digital thread. This includes teams from engineering, manufacturing, IT, quality control, supply chain, and maintenance. Effective communication and knowledge sharing are crucial for seamless data flow and maximizing the benefits of the digital thread.

- Train and educate employees: Provide training and education to employees to ensure they understand the concept of the digital thread and how to utilize the software and tools effectively. Promote a culture of data-driven decision-making and encourage employees to embrace the digital thread as a valuable resource for improving processes and driving innovation.

- Continuously improve and optimize: Implementing the digital thread is an iterative process. Continuously monitor and evaluate the effectiveness of the digital thread implementation, identify areas for improvement, and make necessary adjustments. Foster a culture of continuous improvement to maximize the benefits and stay ahead of the competition.

By following these steps, manufacturers can successfully implement the digital thread, enabling seamless data flow, data-driven decision-making, and unlocking the full potential of digital transformation in the manufacturing industry.

Technologies that Enable the Digital Thread: IoT, AI, and Cloud Computing:

Several technologies play a vital role in enabling the digital thread in manufacturing. Internet of Things (IoT) devices and sensors gather real-time data from machines, products, and processes. Artificial Intelligence (AI) algorithms analyze this data to extract meaningful insights and patterns, driving predictive maintenance, quality control, and process optimization. Cloud computing provides a scalable and secure infrastructure to store, process, and share vast amounts of data across multiple stakeholders and locations, facilitating real-time collaboration and decision-making.

Advanced IIoT, AI-based automation software uses sensors to collect vast amounts of real-time data from each production stage. The process creates a rich digital data-log that’s created through the entire life cycle of each product, helping manufacturers meet the strict quality requirements. In addition, AI-based algorithms analyze the root cause of quality issues, recuts, work interruptions, and defective parts, improving quality and quality control.

Realizing Faster Time-to-Market and Reduced Costs with the Digital Thread

Implementing the digital thread brings numerous benefits to manufacturers. By enabling real-time visibility and access to data, it significantly reduces time-to-market. Design changes, process improvements, and quality enhancements can be implemented swiftly based on real-time insights, leading to shorter production cycles and increased agility. The digital thread also helps in reducing costs by optimizing resource utilization, minimizing rework, and eliminating bottlenecks in the production process.

Building Cross-Functional Teams for Successful Digital Thread Implementation

Successful implementation of the digital thread requires collaboration and coordination among various stakeholders. Building cross-functional teams with representatives from engineering, manufacturing, IT, quality control, and other relevant departments is crucial. These teams can work together to define data standards, establish processes, implement the digital thread software, and drive continuous improvement. Effective communication and knowledge sharing across these teams are essential for seamless data flow and maximizing the benefits of the digital thread.

Summary:

The digital thread is revolutionizing manufacturing by connecting different stages of the product lifecycle through a seamless flow of data and information. It enables real-time insights, data analysis, and informed decision-making, leading to improved efficiency, quality, and innovation. Implementing the digital thread requires careful planning, including defining objectives, assessing existing systems, establishing data standards, and selecting the right software solution.

Technologies such as IoT, AI, and cloud computing play a crucial role in enabling the digital thread. IoT devices and sensors gather real-time data, AI algorithms analyze it to derive insights, and cloud computing provides a scalable and secure infrastructure for data storage and collaboration.

The digital thread offers numerous benefits to manufacturers. It reduces time-to-market by enabling faster decision-making and agility in implementing design changes and process improvements. By optimizing resource utilization and minimizing rework, it also helps reduce costs. Furthermore, the digital thread enhances traceability, enables predictive maintenance, and drives innovation.

To ensure successful implementation, it is important to build cross-functional teams that include representatives from various departments. These teams can collaborate to define data standards, establish processes, implement digital thread software, and drive continuous improvement. Effective communication and knowledge sharing are crucial for seamless data flow and maximizing the benefits of the digital thread.

In conclusion, the digital thread is transforming the manufacturing industry by facilitating seamless data flow and enabling data-driven decision-making. By embracing this concept and leveraging technologies like IoT, AI, and cloud computing, manufacturers can achieve faster time-to-market, reduced costs, improved quality, and increased innovation. Implementing the digital thread requires careful planning, selecting the right software solution, and building cross-functional teams to ensure successful integration and utilization. Embracing the digital thread is a crucial step towards thriving in the modern manufacturing landscape.