Quite a few manufacturers make the mistake of pairing up IIoT and AI, thinking they always go together. It makes sense to make this assumption. If you’re connecting your factory production floor and you want to collect data digitally or make your machinery smart through multiple sensors, you are probably doing so to to derive smart decisions, right?

As I will soon demonstrate, the reality is that the coupling between IIoT and AI should not be taken for granted.

More often than not the two aren’t combined in a single solution, even though they should be., As revolutionary as it may be ,IoT is leaning on data and can’t offer real value without using it. Research indicates that approximately 600 zettabytes of data per year will be created by 2020, while most of it will probably never be used.

What a waste.

It is reasonable to conclude then that IIoT, or the implication of IoT in manufacturing, is no exception and that a lot of the data is generated by the manufacturing sector, but is not necessarily being leveraged. In other words, data that is being collected is often not used to maximize optimization processes via AI based algorithmics. That’s a phenomenon that can be referred to as ‘digital exhaust’.

A dashboard is NOT a Digital Assistant

Let’s think of some IIoT dashboards. What value do they add? Well, these dashboards are presenting data, usually a lot of it. But, that’s not enough to bring efficiency to a new level. Presenting data, even if nicely and in an easy to digest way, isn’t the main potential that lays inside IIoT. In other words, AI based IIoT digital assistants offer a different value.

There’s a huge difference between presenting data or even showing alerts where you still need to figure out what actions to take, versus presenting actionable insights, recommendations and predictions that help you make optimal decisions.

Put another way, data isn’t interesting as is, nor is it very valuable on its own. It’s all about what smarter decisions we can make with that data in hand. While some IIoT based systems are focused on gathering data, I believe that only those who add the ‘decision making layer’ offer a game changing experience.

Let’s take an example from a totally different world. GPS navigation. I am sure that you’ve heard about Waze. Waze is a brilliant navigation app that takes into account various factors and scenarios to offer drivers an end-to-end navigation solution that guides them on how to go from point A to point B. It is somewhat complicated to offer a route when behind the scenes the algorithm needs to calculate traffic, road hazards, user preferences, toll roads, etc.

What experience would users have if Waze chose to only show related alerts along the way? ‘Traffic is really bad close to downtown’, ‘This road seems to be blocked’ ‘A major car accident just occurred one mile ahead’ ‘Road 61, 187 and 3 are toll free’… you get the idea. The difference between gathering data and offering alerts, versus recommending optimal actions that are based on data is huge. It’s a whole different scale.

So yep, some IIoT solutions just offer a smart way to collect manufacturing processes data via connectivity, however the true benefit of that data is still missing.

IIoT and AI – A power Couple

The manufacturing industry is struggling to keep up with today’s ‘rate up, cost down’ dynamics. It’s becoming more and more complex, not to say impossible, for humans to deal with today’s manufacturing challenges without an ‘extra brain’. There lies the added value of AI software.

AI, artificial intelligence if you’ve just landed from outer space 🙂, exceeds human data processing and learning capabilities (want some buzzwords? machine learning, deep learning, and many more algorithms and math methods). There’s no simple way to describe AI, as there are various definitions of the term and many many examples. Some would say it’s the ability of computers to understand, learn and solve problems imitating the way humans think, but at much higher processing power and accuracy.

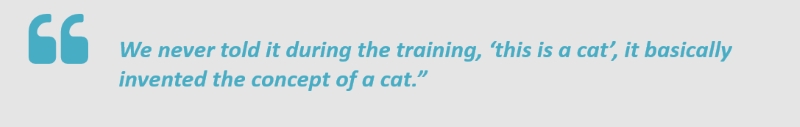

Jeff Dean, from Google Fellow, described it well when he told the the New York Times, commenting on Google’s artificial brain ability to find cat videos using machine learning, ‘We never told it during the training “this is a cat”, it basically invented the concept of a cat.’

Jeff Dean, Google Fellow

But, leveraging AI requires a lot of data processing. If collecting data is the first piece of the non-optimal IIoT puzzle, then context is the second one. The ‘brain’ behind the IIoT solution that you may integrate, as long as that solution has good AI capabilities, calculates both data and context in order to derive actionable insights.

For instance: If a certain tool is located in a specific workstation for a specific period, is it good or bad? Depends. It could be positive if the tool requires maintenance and has reached a maintenance area. It could be a negative outcome if the tool is misplaced and as a result, delays production.

Leveraging AI for problem solving is the real promise behind IIoT, as it utilizes ‘dumb’ data and relies on context to provide actionable insights and add a decision-making layer, at scale, which expands human capabilities up to indefinite parallel calculations.

A real AI based IIoT solution isn’t, therefore, a ‘nice to have’ enrichment but an urgent must-have addition for any factory that wishes to survive and stay competitive, given today’s demand for scale in production and cut in prices. There’s simply no way to do so by depending only on humans, experienced as they may be.

deloitte mention in their article that downtime costs manufacturers $50 billion a year, 42% of which is due to equipment failure. Using AI algorithms to predict equipment failure or to define maintenance procedures (predictive maintenance – PdM), can greatly affect manufacturing by reducing planning maintenance by 20%-50%, increasing equipment uptime by 10%–20% and reducing maintenance costs by 5%-10%.

EDF Group makes a good use case of such predictive maintenance, as they already saved 1 million dollars on machine learning predictive maintenance. I’ll get into some more practical implications of AI in IIoT later.

No ‘one size fits all’

When it comes to finding an optimal algorithm or method, there’s no one size fits all. In order to actually get something out of the data, you first need to decide what pain points you wish to solve. Let me put it this way: you don’t expect your doctor to prescribe antibiotics every time you feel sick, now do you? You expect him/her to apply the right medicine according to his/her diagnostics. Same with AI, there is no one method (i.e. machine learning) that can address all your factories challenges, you need to use a variety of methods and tools.

For example, do you want to increase your factory capacity? Improve quality? Reduce rework (job done right the first time)? Do you need to find ways to cut costs?

Of course, it’s not a decision made by one person, but rather a whole internal process requiring an improvement team of professionals or external experts with relevant experience working with similar companies. Here, it is crucial to focus on IIoT vendors that have experience in AI based optimizations and can suggest best practices and methodologies.

AI solves different problems using different techniques. Here, as well, there’s no ‘one size fits all’. Think of it as a comprehensive tool kit with different types of algorithms and capabilities. Machine learning, for instance, is just one tool in the AI toolbox. Remember the previous Google Fellow quote about the cat? In that case Google used machine learning that requires a lot of historical data. You don’t always have that historical data available in manufacturing. So what do you do until you get to that amount of data? In this case, with a lack of historical data, other AI techniques and algorithms can be quite useful and are considered to be no less advanced.

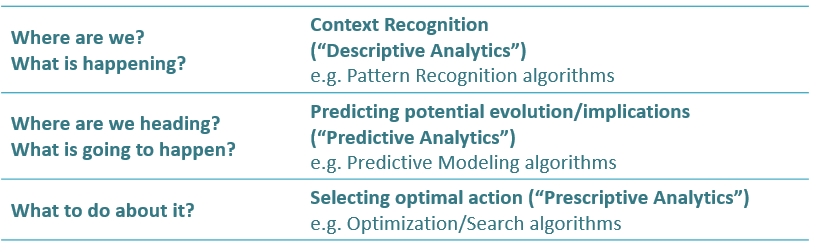

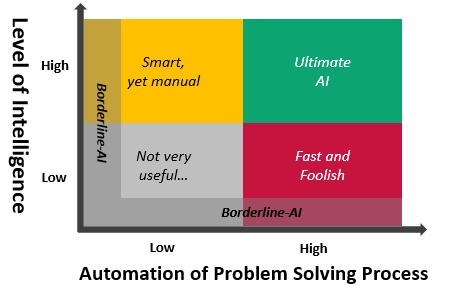

If we try to divide AI techniques by related questions that also reflect the level of intelligence required, here’s how it would look:

Following a more holistic approach and moving the intelligence level required from descriptive to perspective analytics should increase problem solving capabilities. Implementing point solutions that don’t address the full workflow, or are less advanced in their automation level (their ability to solve problems with less human involvement), will result in not fulfilling IIoT potential, to say the least.

In the following metrics, you can see the projected results that are driven by a combination of intelligence and automation at different levels.

Obviously, the ultimate solution, or the most optimal implementation, would be a solution that offers the highest intelligence and automation levels.

AI in Discrete Manufacturing

Here are a few ways in which AI transforms manufacturing in general and discrete manufacturing specifically:

- Prediction of Work Order Latency

One of the main manufacturing pain points is related to production deadlines. When these are not met it’s because of various reasons, such as due date missing, parts standard production time rarely updated to meet the current standards, etc. Using machine learning, it is possible to predict work order latency in order to assess the risk to orders, identify a bottleneck and meet deadlines.

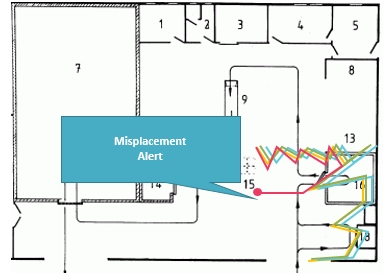

- Part/Asset Misplacement

Work orders, parts and assets can be misplaced, causing production delays and rework (part is being produced or ordered again and when the original part is eventually found it is usually scraped). Using AI, an IIoT software can alert relevant users upon deviation from the expected production trail. - Optimize Tool Maintenance CyclesMaintenance cycles ‘the old way’, often periodically or based on a simple counter. This can lead to quality issues or low Overall Equipment Effectiveness (OEE). Using AI, an IIoT solution can predict and recommend tool maintenance based on actual usage and current conditions.

- Analyze Root Cause of Quality Issues and Defective Parts

Quality issues such as defective materials and parts are one of the major pain points in the manufacturing industry. Using AI, an IIoT solution can help identify similarity measures between defective goods and their root causes, whether it’s caused by a combination of a specific operator/workstation, a tool that hasn’t recieved proper maintenance, or another reason, and act upon them.

- Identify Bottlenecks and Act Upon Them

Bottlenecks limit production capacity. Using an AI,based IIoT solution you can predict a bottleneck based on historical data of the production time of a certain part (learning its historical movement), knowledge of the planned workload and impediments that are collected in real time on the shop floor.

For example: If a tool is ‘sitting’ vacant too long while a work order attached is taking too long, the AI algorithm will identify it and suggest using the ‘unemployed’ tool to prevent a bottleneck. By the way, in this case it will also issue a warning about work order latency – killing 2 birds with one stone.

The following image can simplify what AI and IIoT can achieve together:

Summary

I would always recommend ensuring your IIoT solution supports you with more than just collecting data and providing alerts. In order to cope with tight schedules and growing volumes of production, you will have to have an AI based solution that collects massive data, runs multiple processes and sends intelligent alerts and recommendations. At the end of the day, you can and should expect your IIoT solution to be able to offer you solutions, not just identify problems.

Be sure the IIoT solution you choose also has a well planned product road map and can adapt and evolve the algorithm to industrial challenges as well as unique situations and environments, as these will surely change over time, and they tend to do so these days more often than ever before.