In the bustling world of manufacturing and production, staying ahead of the curve isn’t just a strategy—it’s a necessity. Enter Industry 4.0, the latest revolution in manufacturing technology, marked by automation, leveraging data, and manufacturing technologies. It’s a brave new world where AI-based software solutions play a pivotal role in streamlining production processes, enhancing efficiency, and minimizing downtime. This blog post explores the significance of AI technology within Industry 4.0, delves into their key components, and outlines effective implementation strategies.

The Role of Digital Solutions in Industry 4.0

Industry 4.0 has ushered in an era where the digital transformation of manufacturing processes is no longer optional but imperative. At the forefront of this transformation are AI-based solutions, which not only streamline production processes but also enhance the interconnectedness of operations across the board. AI technology acts as a catalyst for superior collaboration, breaking down silos within factories, facilitating seamless communication between different manufacturing sites, and strengthening the links with suppliers.

This advanced level of connectivity means that data and insights can be shared in real-time across the entire supply chain, ensuring that all parties are on the same page. For instance, if a machine on the production floor experiences an unexpected downtime, AI systems can immediately notify relevant stakeholders and automatically reschedule its tasks to other machines.aThis real-time information exchange helps in preventing delays, optimizing inventory levels, and maintaining a smooth production flow.

Moreover, AI-driven analytics allow for the aggregation and analysis of data from diverse sources, enabling a holistic view of operations. By leveraging predictive analytics, manufacturers can anticipate market demands, adjust production schedules in real-time, and collaborate more effectively with partners to meet these demands. This predictive capability fosters a proactive rather than reactive approach, allowing for more strategic decision-making and planning.

AI-based software solutions are not just about monitoring and optimizing the production process; they are about creating a more integrated, transparent, and collaborative manufacturing ecosystem. This interconnected approach ensures that every link in the production chain, from the factory floor to the supplier’s warehouse, is strengthened, leading to more efficient, responsive, and adaptable manufacturing operations. Through these advanced technologies, Industry 4.0 is setting the stage for a future where connectivity and collaboration are key drivers of success.

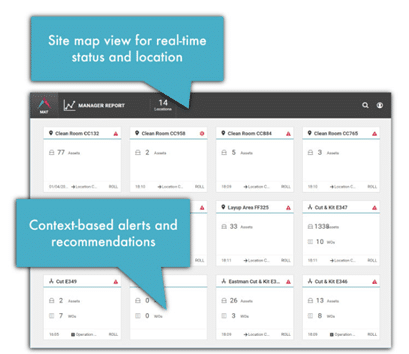

In essence, the technology serves as the nervous system of a manufacturing unit, enabling decision-makers to monitor, analyze, and react wisely to the pulse of production operations. This interconnected approach ensures that every link in the production chain, from the factory floor to the supplier’s warehouse, is strengthened, leading to more efficient, responsive, and adaptable manufacturing operations. These software solutions facilitate tracking production in manufacturing by displaying key performance indicators (KPIs), such as output rates, quality levels, machine uptime and the status. This real-time visibility ensures that managers can make informed decisions quickly, reducing production downtime and keeping productivity at its peak.

Key Components of AI solutions for Connected Factory

The key components of AI solutions for connected factory starts with production process monitoring and is the foundation to their effectiveness in the fast-paced manufacturing environment. Next comes the analytics and knowledge layer. On top comes the AI layer with predictions, recommendations and process optimizations. Let’s delve deeper into each element to understand its significance and functionality:

Real-Time Data Visualization

Real-time data visualization enables data transformation from raw data into visual formats such as graphs, charts, and gauges. These visual representations are designed to depict various metrics critical to the manufacturing process, including production speed, quality control, and equipment efficiency. By simplifying complex data into an easily digestible format, real-time visualization aids in swift decision-making processes. This instant visibility into operations allows managers and operators to quickly identify and address production issues, enhancing overall efficiency and productivity.

Predictive Analytics

Predictive analytics are the core of AI capabilities, leveraging historical data and behavior to anticipate future production trends and outcomes. This component employs sophisticated algorithms and machine learning techniques to predict potential disruptions, such as bottlenecks and delays; forecast production capacities; and identify opportunities for process optimization. Predictive analytics can significantly impact strategic planning, enabling businesses to proactively manage resources, schedule maintenance to minimize downtime, and adjust production schedules to meet demand forecasts, thereby ensuring a smoother, more efficient production flow.

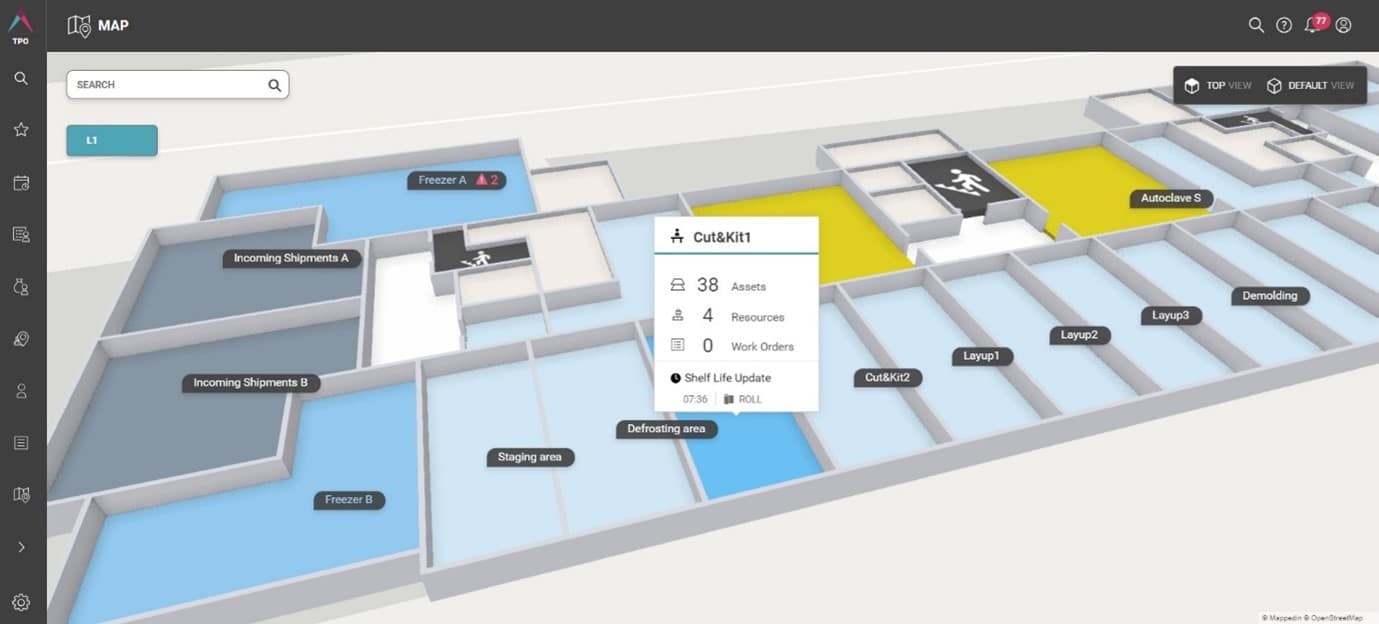

Plataine Map View – interactive map, presenting location based alerts.

Customizable Alerts and Notifications

Customizable alerts and notifications are critical for maintaining continuous production process tracking. This feature allows users to set specific criteria for alerts, such as deviations in production levels, equipment performance anomalies, or quality control issues. By receiving immediate notifications about these critical events, management and floor operators can take prompt action to address problems, minimizing delays and reducing downtime. This real-time alert system ensures that potential issues are not just detected but are acted upon quickly, maintaining the integrity of the production process and safeguarding product quality.

Supreme Connectivity across the entire factory

Cloud-based solutions enable connectivity and superior collaboration within the factory, between different sites and with suppliers. This connectivity boosts operational efficiency and supply chain collaboration by having all the operations streamlined.

In addition, the ability to integrate with other systems and software is what transforms them from a standalone tool into a comprehensive monitoring and management system. Integration capabilities of AI cloud solutions allow seamless communication between various organizational systems. It enables the aggregation and analysis of data from different stages of production and various departments, facilitating coordinated decision-making and strategic planning across the organization.

These key components collectively enhance the effectiveness of AI based solutions leading to a fully connected smart factory. By offering real-time insights, predictive foresight, instant alerts, and seamless integration, now manufacturers can navigate the complexities of modern production environments with greater agility and precision, aligning perfectly with the goals and challenges of Industry 4.0.

Implementation Strategies of AI technology

Implementing digital solutions effectively in a manufacturing environment involves a meticulous and strategic approach. Here’s a deeper dive into the key strategies for a successful implementation:

Define Clear Objectives

The journey towards implementing digital solution begins with clarity of purpose. Establishing clear objectives is crucial for steering the direction of the implementation. Objectives might range from reducing machine downtime, enhancing the quality of output, to elevating overall operational efficiency. This initial step is pivotal as it informs the choice of features and functionalities that your digital solution will need to possess. It’s about understanding the end goal to ensure that the solution meets your manufacturing needs effectively.

Involve End-Users in the Design Process

The design and usability of software solutions are critical to their effectiveness. To achieve a design that resonates well with the end-users, their involvement in the design process is indispensable. Operators, managers, and engineers know the intricacies of daily operations and are best placed to provide insights into what features will be most beneficial. This collaborative approach not only ensures that the solution is tailored to meet the specific needs of the users but also fosters a sense of ownership and acceptance among them. The outcome is a user-friendly interface that enhances accessibility and relevance of the information presented, making it easier for users to engage with and derive value from the platform.

Ensure Scalability

In the dynamic environment of manufacturing, the needs and scales of operation can evolve rapidly. A digital solution that’s scalable is thus essential. Scalability ensures that the solution can accommodate growing volumes of data and integrate seamlessly with emerging technologies. This foresight is not just about preparing for increased demand but also about ensuring the longevity and continued relevance of the solution. Choosing a scalable solution means protecting your investment and guaranteeing that the tool remains valuable and adaptable to future requirements.

Train Your Team

The effectiveness of digital solutions is significantly influenced by the proficiency of the users. Comprehensive training is essential to equip your team with the necessary skills to navigate, utilize, and interpret the data from the platform effectively. Beyond initial training, ongoing sessions can ensure that the team remains conversant with any new features and functionalities, reinforcing best practices and ensuring that the solution is utilized to its full potential. This continuous investment in training underscores the commitment to maximizing the benefits and fostering a culture of data-driven decision-making.

Monitor and Iterate

Software implementation is a continuous journey, not a destination. Regular monitoring and evaluation of the performance are crucial to understanding its impact and effectiveness. Soliciting feedback from users can provide invaluable insights into how the solution can be refined and improved. Be prepared to iterate and make necessary adjustments to ensure that the solution evolves in response to changing needs and continues to meet the operational demands of your production processes effectively. This iterative process is key to maintaining the relevance and utility over time, ensuring it remains a powerful tool in your manufacturing operations.

Each of these strategies plays a vital role in the successful of AI based solutions in the manufacturing sector, paving the way for enhanced productivity, efficiency, and data-driven decision-making in the era of Industry 4.0.

As we conclude our journey through the transformative world of Industry 4.0, it’s evident that AI-driven digital solutions are at the forefront of manufacturing evolution. Far from being a fleeting trend, these innovations are pivotal, offering a futuristic command center at our fingertips and converting complex data into actionable insights for swift, informed decision-making. AI acts as the ultimate navigator through the complexities of modern manufacturing, providing a clear overview of operations, identifying inefficiencies, and leveraging predictive analytics to anticipate and mitigate challenges before they arise.

Crucially, AI’s role extends beyond the confines of individual factories, enhancing connectivity and fostering seamless collaboration across various sites and with suppliers. This interconnected approach ensures a cohesive manufacturing ecosystem, where information flows freely, aligning operations and enabling a proactive stance on production management.

In essence, embracing AI-based solutions is not just about keeping pace with technological advancements; it’s about positioning our manufacturing operations at the vanguard of innovation. This era promises not only to streamline production processes but also to redefine how we approach collaboration and connectivity in the manufacturing sector. As we stand on the brink of this new dawn in manufacturing, powered by AI’s clarity and efficiency, let’s move forward with an open mind, ready to seize the myriad opportunities that this digital revolution holds. Here’s to a future where technology and human ingenuity converge to create a more efficient, interconnected, and innovative manufacturing landscape.