As hard to believe as it is, a whole year has passed since we reviewed the upcoming trends for 2019. And now, here we are again! This time, we’ll cover the hottest emerging technologies for the new year as seen in the media, but also with our own perspective, based on our past year of experience engaging with the world’s top manufacturers.

Looking back before moving forward

Before we dive into the new trends of 2020, let’s take a quick look at some of the key trends of 2019 (many of them were mentioned by us a year ago) these trends will stick around and continue to transform the field even further:

- The digital twin: Creating a digital replica of physical products or procedures helps manufacturers optimize countless aspects of the process and creates a superior physical version at the end. The digital twin technology is the basis for many advanced Industry 4.0 technologies.

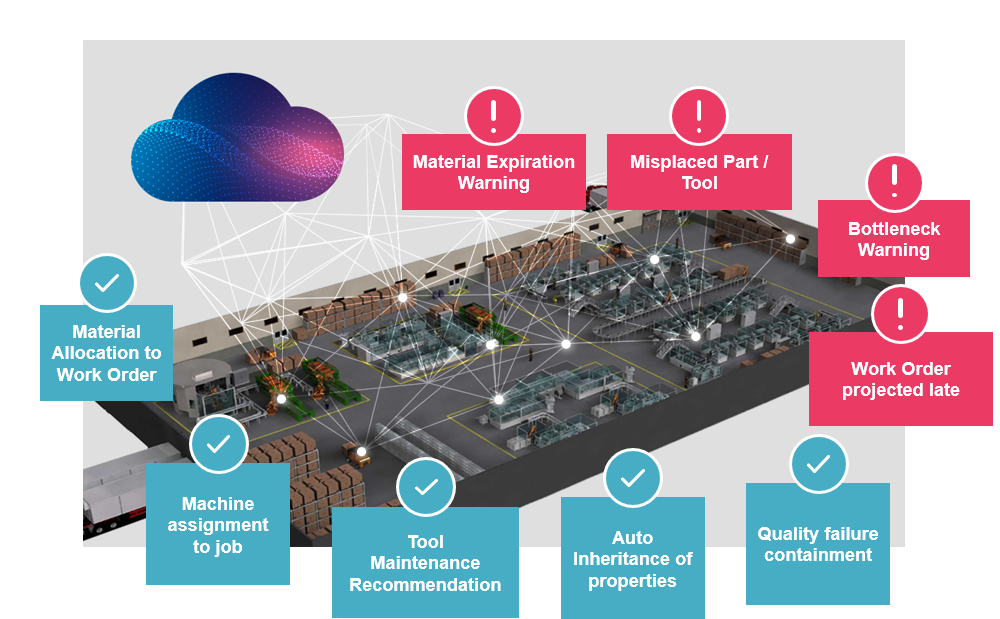

- Artificial Intelligence (AI): Smart algorithms that make predictions and smart recommendations to professionals in the field is a true revolution in the manufacturing world. Here are some concrete use cases to help you understand the gist of it. In 2020, we can expect these technologies to only get smarter and more beneficial. Spoiler alert: the new trends for 2020 combine this technology with another exciting one for extra optimization.

- Robotics and automation: Using industrial robots and implementing automation scripts speed-up and optimize many processes by eliminating human error and reaching a quality result in a fraction of the time it used to take. Robots will also keep people safer, taking the load off risky production floor functions.

- Industrial cybersecurity: Cyber security is rapidly becoming a critical component of effective management in manufacturing. Therefore, it is important to implement a Cyber Security Policy and make it a priority across all the organization. This requires following a series of steps in assessing, identifying, and implementing tools/ methods to reach and maintain the highest cyber security standards.

- Professional experts: While technically not a technology, human expertise involving new technologies becomes increasingly important in the manufacturing industry and will continue to be crucial as more advancements are added to factories.

- 5G: The promise of improved connectivity has been buzzing in 2019 and continues to do so, thus enabling manufacturers to minimize downtime and enjoy network connectivity at a much higher level, that is critical for their production processes.

- Wearables, AR, and VR: These technologies add another layer to manufacturing businesses, literally. From smart glassesthat present every corner of the factory, to smart tools that walk workers through every step of the manufacturing process

A new decade – New trends, new technologies

And now, without further ado, here are the emerging trends we expect will dominate 2020.

Some may seem familiar but promise to be more advanced and offer much clearer applications in this exciting new year.

- IIoT? Not without AI

Long gone are the days of manual manufacturing. No more are humans the only ones doing all the decision making. In 2020 more and more advanced manufacturers will embrace the most advanced technologies in order to win the current manufacturing challenges.

Today, AI joins hands with sensors to offer the missing element, and I don’t mean data collection and basic analytics, but rather, I talk about clear and actionable recommendations that are delivered in a visualized and friendly manner. Expectations from technologies will rise in 2020 and they will need to form an optimization boost that offers specific recommendations.

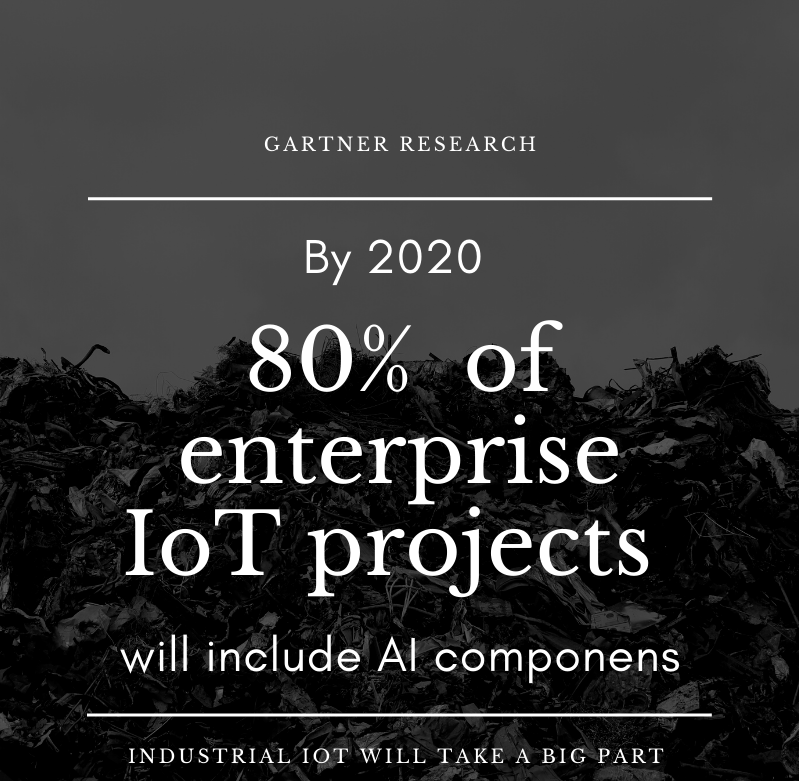

The combination of these two technologies (AI and IIoT) is so strong that, according to Gartner, we will see 80% of enterprise IoT projects include AI components by 2022.

The implementation of AI-based technologies depends on the demonstration of ROI, and as companies will be able to do so more effectively, the technology will be embraced by other manufacturers, as well as additional sections within the same factory.

- Additive manufacturing and 3D printing

Large-scale 3D printing brings this transformative technology to manufacturers around the world. This year, we released the story of CTC GmbH, an Airbus company that adopted Plataine’s solutions for 3D-printed aerospace parts in ways that enabled the company to optimize its production process. The many benefits offered to companies that march forward and embrace additive manufacturing include shorter time to market, higher flexibility, improved quality and an increase in profitability.

In 2020, we can expect additive manufacturing to offer more options than ever, with a versatile portfolio of applications that will cater to specific use cases and needs. In other words, a growing number of manufacturers will either find or develop the additive manufacturing technology that suits their factory and customers. Another process we’re excited to see improve is the 3D printing procedure itself, which will become easier to simulate and predict, thus making it more efficient than ever.

- Edge computing

In a nutshell, Edge computing technologies for manufacturing collect, filter and analyze data based on a predetermined distribution hierarchy, and store the data in different localized or cloud locations, by relevance.

In 2020, more manufacturers will implement edge computing solutions and therefore will enjoy benefits such as reduced latency and improved availability (thanks to this smart distribution paradigm). This will help create faster manufacturing procedures that will eventually set a new standard for the industry.

- Sustainability:

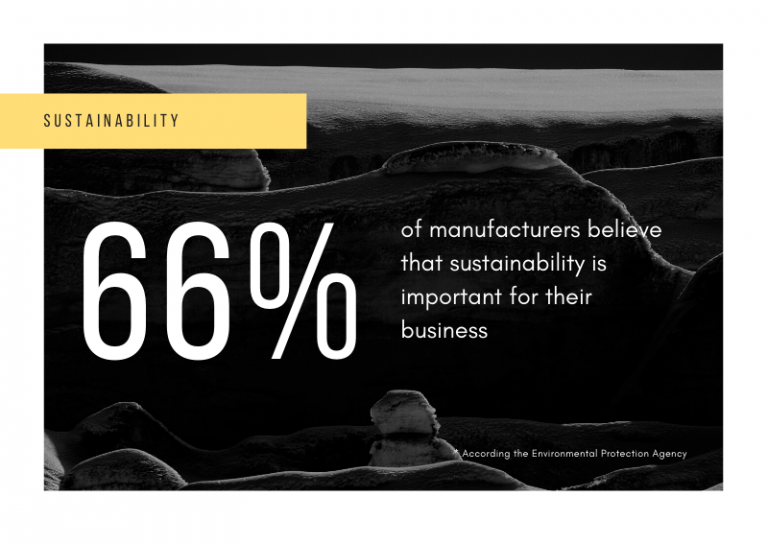

When we think about the benefits of reducing waste and opting for green energy, what first comes to mind has less to do with business and more with saving our planet. But there’s also clear ROI with saving energy, expensive materials or any other resource from going to waste and supporting a worthy cause, which is why many manufacturers consider sustainability a crucial initiative for their business in 2020. It just so happens that 66% of manufacturers believe that sustainability is important for their business.

- Optimizing the supply chain:

Focusing on just a single part of the process will not be enough in 2020. This year, manufacturers will take a step back and examine their entire supply chain to identify weak spots that need to be polished and optimized for a meaningful boost in production.

Every step and each participant will be considered, as well as the transition from one process to another. This enables companies to significantly cut their time to market and utilize their workforce, particularly when it comes to employees in charge of communicating between different divisions or those focused on quality control errors. The improved communication will also boost security levels, as less information will leak while transitioning between distant and disconnected parts of the chain.

We’ve long discussed the importance of supply chain collaboration and in 2020, we expect others to be talking about it as well. Digitization obviously plays a key role in allowing the new, Industry 4.0 state of mind to take place, as the Digital Supply Network (DSN) provides the core data for everyone involved.

Summary

Unlike many other verticals, disrupting the manufacturing industry takes time. In 2019, we began to see some of the biggest dreams of the field become a reality, and in 2020 we will witness even more exciting and transformative procedures. The industry still has a lot of work to do but is headed in the right direction. For today’s manufacturers, this is great news