Time sensitive material Manager

Freezer Management Software tracks materials that are time and temperature sensitive, such as composites pre-pregs and resins, throughout production, ensuring higher quality while avoiding re-work and waste.

TIME SENSITIVE MATERIAL MANAGER:

Ensures optimal material selection for jobs based on properties, status and AI quality data.

Prevents usage of expired material or material likely to expire by the time work order is completed.

Enables complete traceability through the entire manufacturing process as the Digital Twin records every aspect of an assets cycle from raw material to end product.

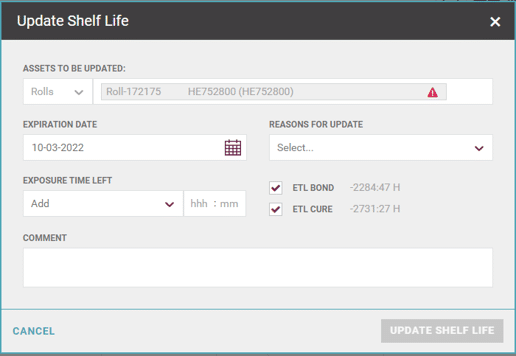

Automatic tracking of remaining shelf-life and expiration

Optimal, AI-based material assignment to jobs

Alerts prevent material expiration

Complete traceability and quality control

Integrated Map for Factory Digital Twin

Visual asset tracking and location based alerts for better decision making

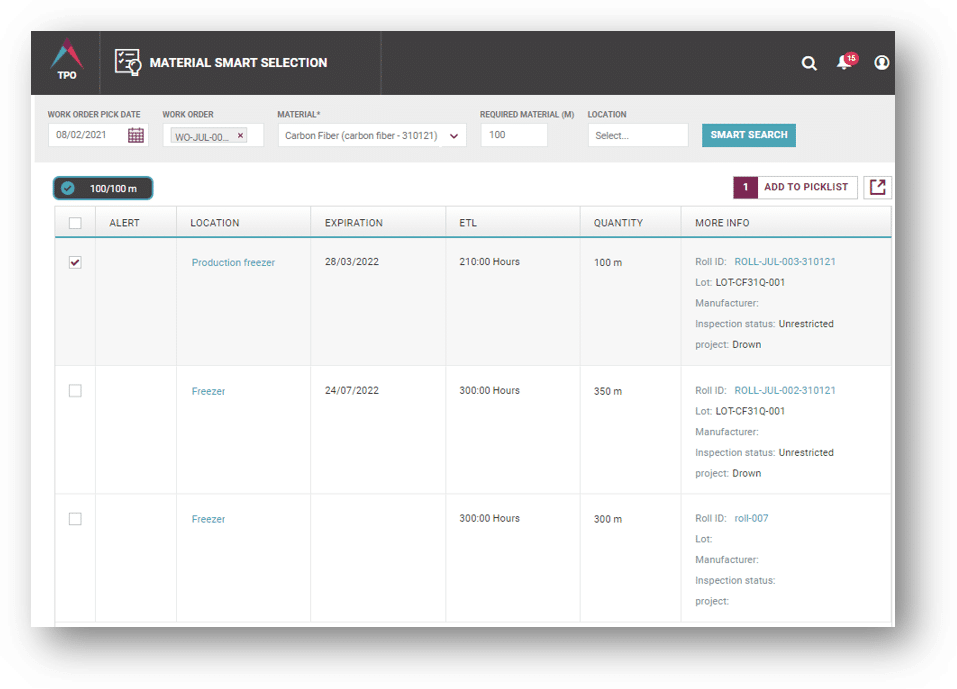

Smart Material Selection: Maximized Inventory On Hand

Digital Assistants present alerts & recommendations:

- Expected amount of material needed

- Material expiration date and remaining ETL

- Work order due date

- Expected duration of work order

The solution maximizes short rolls usage, avoids use of expired materials and improves first-time-right quality.

Eliminate shelf life related quality issues

Time Sensitive Material management releases you from manually tracking sensitive material giving you a paperless production.

The Software tracks & traces location, condition and status of all materials and kits and automatically calculates exposure time.

Smart AI-based algorithms assign the right material for the next work order ensuring materials will be valid by the time the part reaches curing.

CUSTOMERS ARE SAYING

READ THE FULL CASE STUDY

READ THE FULL CASE STUDY