Welcome to 2024, a year where the digital manufacturing sector is not just evolving; it’s revolutionizing! Industry 4.0 is no longer a buzzword but a reality that’s transforming how we produce, process, and perceive manufacturing. Let’s dive into the fascinating world of digital manufacturing and uncover the key trends that are making waves this year.

Smart Factories are the Future

Step into the future with smart factories – the new stars of the manufacturing sector. These factories are more than just a collection of machines; they are intelligent ecosystems. Powered by Industry 4.0 technologies, these factories are the epitome of efficiency and innovation. Picture this: Machines communicating seamlessly, AI optimizing production processes, and IoT devices monitoring every aspect of the operation. This is not just a factory; it’s a symphony of technology and innovation playing the tune of future manufacturing!

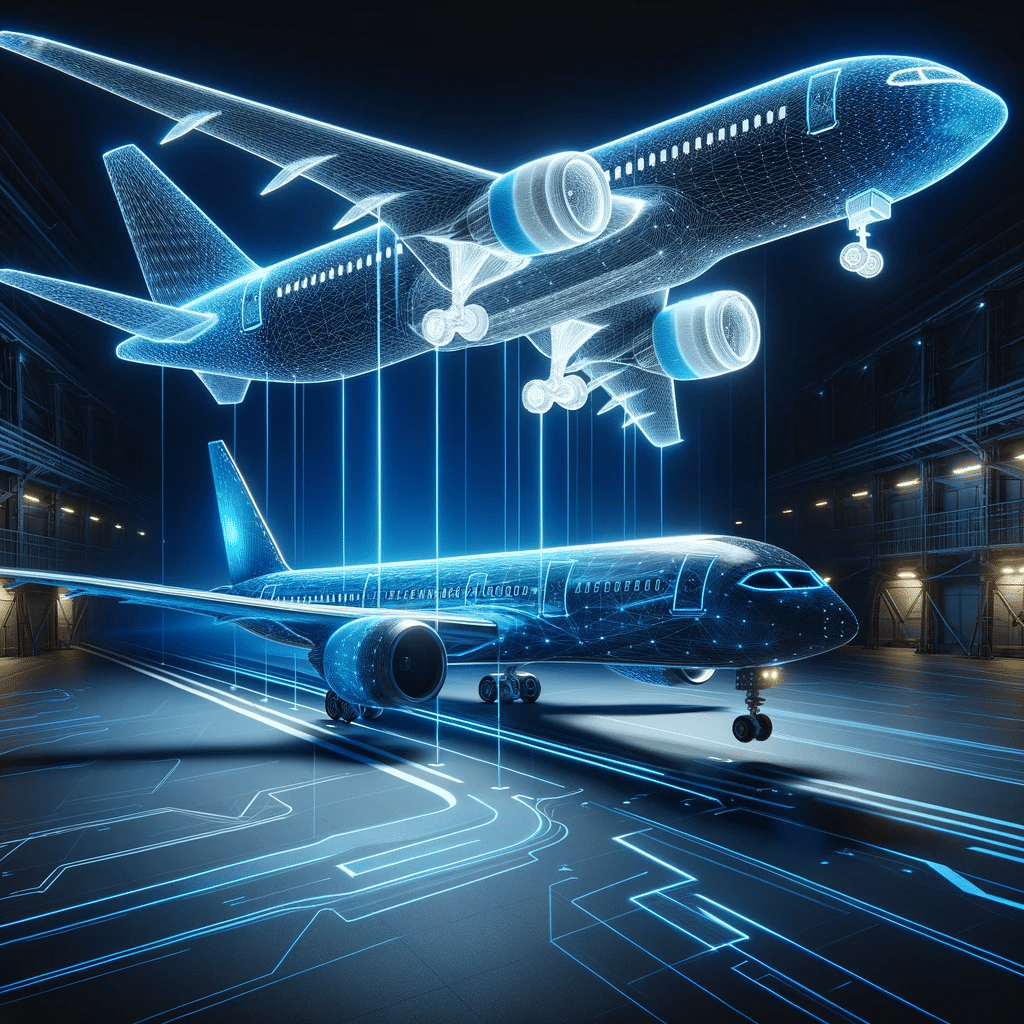

Predictive Maintenance and Digital Twin is a Must

Say goodbye to the era of unexpected downtimes and unwelcome surprises with the advent of predictive maintenance. In the transformative world of 2024, the ability to foresee and prevent problems before they occur is not a product of magic but a testament to technological advancement. Leveraging the power of data analytics and AI, manufacturers are now able to anticipate equipment failures, ensuring that they can address issues proactively rather than reactively. This approach not only saves time and resources but also significantly enhances operational efficiency.

The role of digital twins in this technological revolution cannot be overstated. These virtual replicas of physical systems go far beyond being mere high-tech simulations. They serve as indispensable tools for in-depth testing, detailed analysis, and continuous improvement of product designs and manufacturing processes. By mirroring the real-world environment, digital twins allow for safe experimentation and optimization, leading to better products and more efficient production methods. Moreover, they bridge the gap between the physical and digital realms, enabling manufacturers to fine-tune their machines and processes with unparalleled precision.

In essence, predictive maintenance and digital twins collectively form a powerful duo in the modern manufacturing landscape. They not only optimize current operations but also lay the groundwork for future advancements. These technologies, akin to a crystal ball, provide manufacturers with an invaluable insight into the future of their operations, allowing them to stay one step ahead in a highly competitive and ever-evolving industry.

Supply Chain Management for Full Visibility and Efficiency

The manufacturing sector is undergoing significant transformation in supply chain management, propelled by advanced technologies. These innovations provide a comprehensive, efficient view of the entire supply chain, from raw material procurement to the delivery of finished products. Integrating IoT, AI, and advanced analytics, manufacturers achieve a detailed understanding of their operations, ensuring optimal performance at every stage.

The adoption of these technologies will being multiple advantages in to the new year. Real-time tracking of materials and products allows for immediate identification and resolution of disruptions, ensuring a seamless operational flow and timely deliveries. Predictive analytics play a crucial role in forecasting demands and adjusting supply strategies, leading to a more agile and responsive supply chain.

These advanced systems also improve communication and coordination across the supply chain, fostering better collaboration and alignment among all stakeholders. This enhanced integration results in a synchronized process that not only reduces waste but also maximizes productivity and efficiency.

Ultimately, the supply chain management of 2024 will represents a paradigm shift in manufacturing. It’s not just about managing the flow of goods; it’s about creating a cohesive, efficient, and proactive system. This revolution in supply chain management marks a significant stride towards a more connected, resilient, and efficient manufacturing landscape.

Overcoming Workforce Challenges with Technology

In the field of digital manufacturing, overcoming workforce challenges is crucial, and advanced technology offers innovative solutions. Collaborative robots (cobots) work alongside humans, handling repetitive tasks and improving workplace safety and efficiency. These cobots are adaptable, easing the physical strain on workers and enhancing productivity. AI-enhanced training programs are another key innovation, offering personalized learning experiences that adapt to individual employees’ needs, filling skill gaps, and enhancing overall expertise. Augmented reality (AR) further revolutionizes the sector by providing real-time guidance for complex tasks, enhancing precision and reducing errors. These technologies collectively foster a more engaged workforce, automating routine tasks to focus on creativity and problem-solving. This not only increases job satisfaction but also attracts younger, tech-savvy talent. By integrating these technological advancements, the digital manufacturing sector effectively addresses workforce challenges, creating a more efficient, safe, and enjoyable work environment while enhancing the human element in manufacturing.

Sustainable Manufacturing – Not Only Net Zero

Sustainable manufacturing transcends the goal of merely reducing carbon footprints, embodying a holistic approach to production. This paradigm shift incorporates energy-efficient processes and the integration of renewable energy sources like solar and wind, significantly cutting greenhouse gas emissions while also reducing operational costs. The adoption of eco-friendly materials is also paramount, with a focus on biodegradable, recycled, or sustainably sourced inputs, reflecting a commitment to minimizing environmental impact across product lifecycles.

Recycling and reusing materials are crucial, with closed-loop systems reprocessing waste back into production, enhancing resource efficiency. This extends to responsible supply chain management, where manufacturers select suppliers based on their environmental practices, promoting broader ecological responsibility.

This comprehensive approach to sustainability is not just environmentally driven but also an economic and ethical strategy. It aligns with increasing consumer demand for responsible products and prepares businesses for future environmental regulations, thus securing their long-term viability and commitment to protecting future generations.

The Rise of Generative AI

The digital manufacturing landscape is witnessing a significant trend: the rise of Generative AI. This cutting-edge technology is revolutionizing how products are designed, developed, and delivered. Generative AI refers to algorithms that can generate new data similar to the data they were trained on, enabling them to create everything from optimized product designs to efficient manufacturing processes. In the realm of digital manufacturing, this translates to AI systems that can design parts, predict optimal material combinations, and even simulate entire production processes before a single physical prototype is made. This not only accelerates the product development cycle but also drastically reduces costs and waste, as manufacturers can foresee and rectify potential issues in the virtual realm. Moreover, Generative AI is fostering a new era of customization. Products can now be tailored to specific customer needs with unprecedented precision and efficiency, opening up new markets and opportunities. The implementation of Generative AI in manufacturing workflows marks a shift towards more innovative, efficient, and customer-centric production models, solidifying its role as a key trend in the digital manufacturing sector of the upcoming year.

Fostering Innovation to Stay Competitive and Grow

Innovation is the fuel that keeps the digital manufacturing sector running. In 2024, fostering a culture of innovation is not just a nice-to-have; it’s a must-have. Manufacturers are continuously experimenting with new technologies, processes, and business models to stay ahead of the curve. In an industry where change is the only constant, being innovative is not just about survival; it’s about thriving.

As we journey through 2024, it’s clear that the digital manufacturing sector is on an exciting path. With smart factories, advanced technologies, and a focus on sustainability and innovation, the future of manufacturing is not just efficient; it’s transformative. So, let’s embrace these trends and gear up for a year that’s not just about making products but about making a difference. Welcome to the exciting world of digital manufacturing in 2024!