Tips to reduce costs and maximize manufacturing yield during times of global changes and uncertainties

It was Charles Darwin who famously said: “It is not the strongest of the species that survives… It is the one that is the most adaptable to change“, and indeed, as in nature, it holds true in business and economics.

In these unprecedented times of a global pandemic, it’s important to work both, effectively (doing the right things) and efficiently (doing things right). To do so, you want to make sure that your facility is agile and ready.

We have prepared a short test, to estimate where you stand and how you can become smart, improve the overall agility and efficiency of your composites production operations, reduce production costs and maximize production yield. Let’s take it step by step;

Smart factory in a nutshell

The smart factory concept represents a revolutionary transformation, already forming the future of industrial manufacturing. Such factories optimize their resources’ utilization and leverage technology to improve quality & quality control, shorten manufacturing cycles, boost production and minimize costs and waste, all in order to remain competitive and viable.

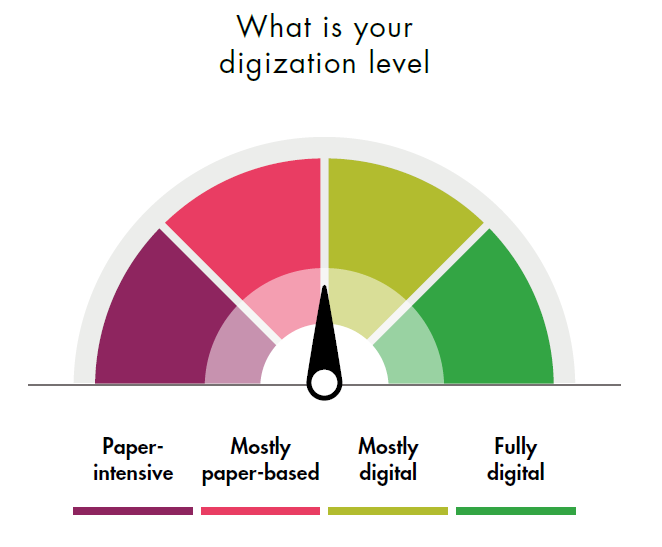

- What is your digitization level?

Digitization is the first step you need to take, to make your operations more efficient and reduce re-work.

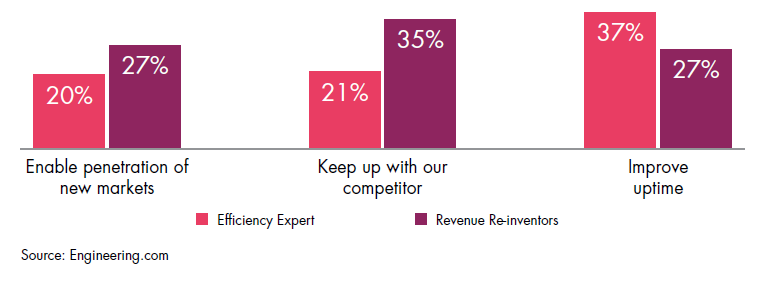

A study by Engineering.com presented the following top reasons for digitization:

- Penetration to new markets

- Keeping up with competition

- Uptime improvement

Test yourself:

How close are you to the green zone?

Consider the digital procedures and tracking mechanisms you’re using to locate, track and measure your production processes.

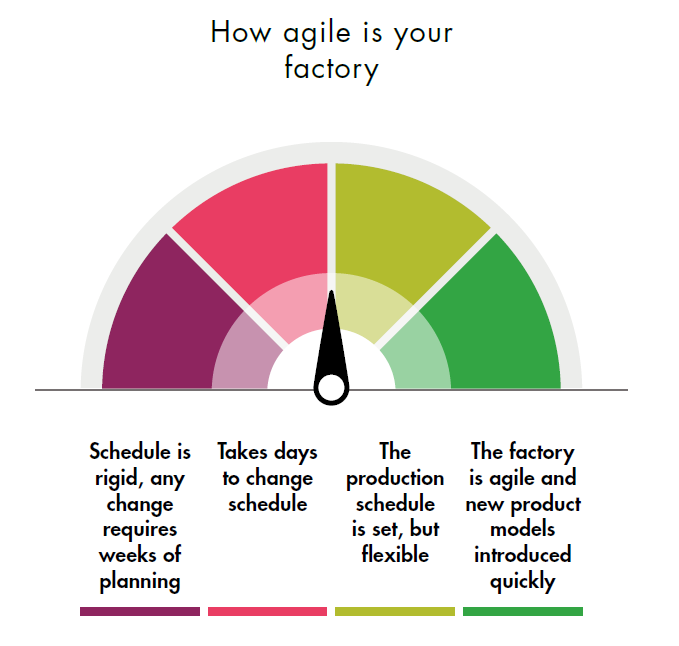

- How agile is your factory?

Agile manufacturing means flexible manufacturing, enabling you to adopt to the changing circumstances and demands Imposed by today’s dynamic market. The agile approach goes hand in hand with lean manufacturing – the leaner your business is, the quicker it gets back on its feet, shortening time to market.

Test yourself

- How long does it takes you to implement schedule changes?

- Could such changes happen faster or slower than before?

- If a rush order comes in, what will it require from you to reschedule other orders?

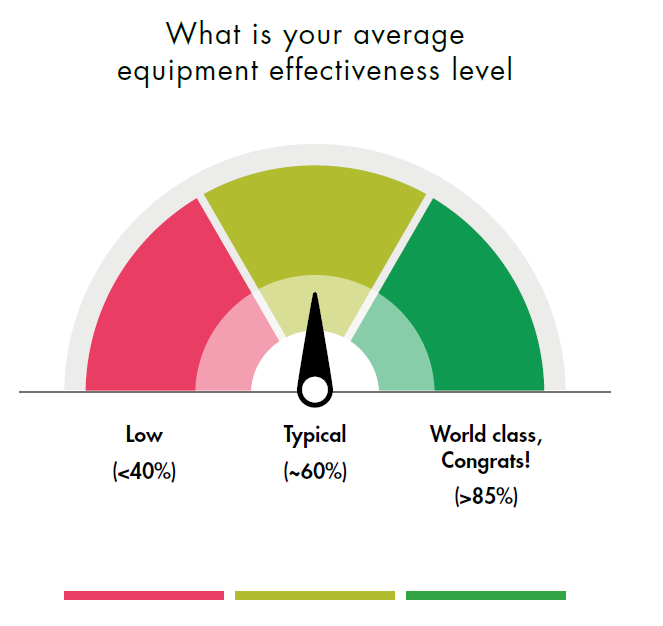

3- What is your average equipment effectiveness level (OEE)?

Measuring your OEE should help you produce more, using your existing resources. OEE assigns numerical value to improvement opportunity, checking the level of availability, quality and overall performance of equipment, machinery and tools in production.

Test yourself

- Do you measure OEE? If not,beginning to do so would be a good starting point.

- How do you measure up compared to industry benchmarks?

- Evaluate the steps needed to improve your OEE and measure it more accurately.

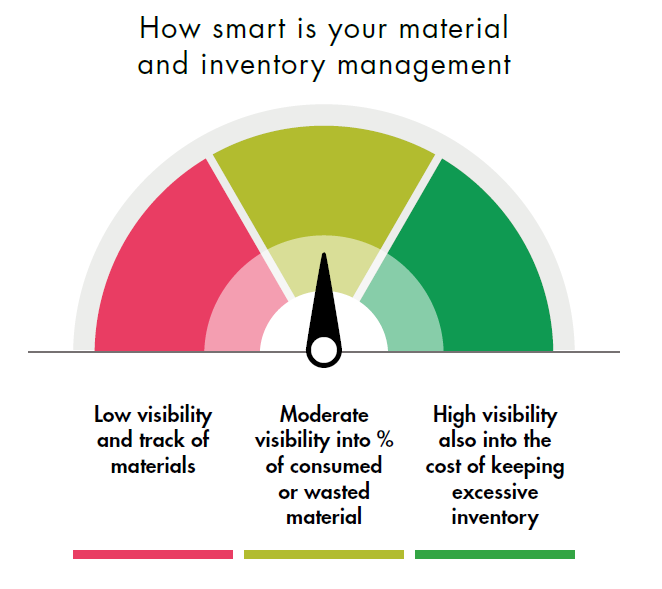

4- How smart is your material and inventory management is Inventory management optimization takes a major role in the smart factory concept, this is even more important in times of global uncertainties, it is imperative to get full visibility and control over your inventory in order to save material, utilize waste and ensure that enough material is available for current and future production flow.

Test yourself

- How do you keep track of your material?

- Do you have complete and accurate visibility?

- How much is consumed and what % is wasted or about to expire?

- What is the cost of keeping your excessive inventory?

So… how close to the green area are you?

Take the needed steps to be an industry leader and move closer to the green scale by adopting advanced technologies that can assist you to save costs, maximize manufacturing yield, get increased visibility and keep your organization lean and efficient, to meet the dynamic needs of today’s market, and stay viable and competitive.

Learn more about the agile and smart factory here.

Our experts will be glad to assist you to estimate how agile your factory is, just reach out!