Waltham, MA, January 19th, 2023 – Plataine, a leading provider of AI-based manufacturing optimization solutions, has released a new version of its FabricOptimizer offering to address the supply chain and workforce challenges Aerospace manufacturers face today. Plataine’s new version of the FabricOptimizer solution allows advanced manufacturers to reach increased production rates, full process automation and further maximize material utilization by creating efficient cut plans. The new capabilities include a material procurement simulator, an automatic ‘nesting around defects’ solution, and detailed reports to improve yield and ‘first-time right’ score.

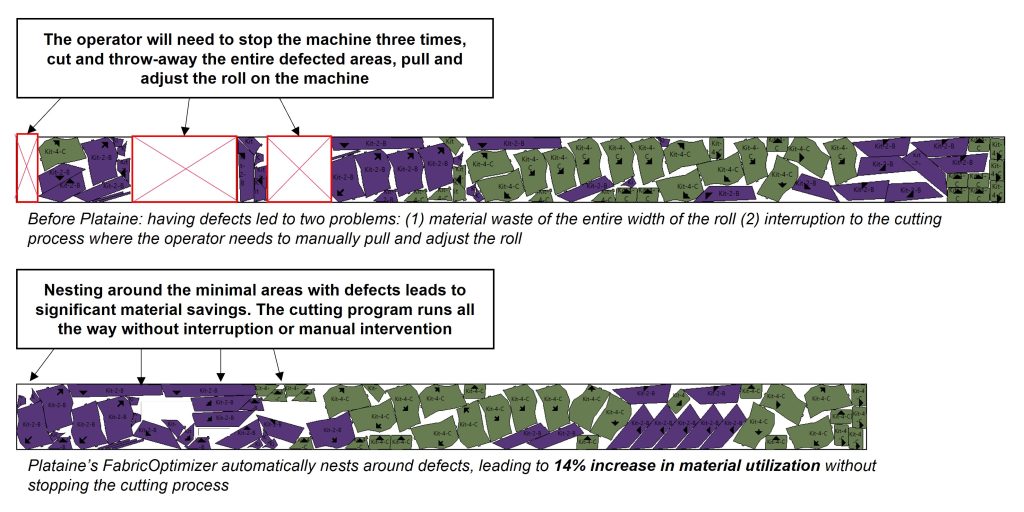

Plataine’s new AI-based ‘nesting around defects’ solution, enables manufacturers to deliver the most optimized dynamic cut plans that make the best possible use of material rolls with known defects. These new capabilities help to reduce errors, rework and material waste leading to continuous process improvement. Users can now retrieve information of known defects on rolls, ignore specific parts of a roll when nesting and maximize material utilization. Quality is ensured, while the amount of material going to waste is minimized, improving customers’ ability to maximize on-hand inventory, especially during times where lead time for receiving new material is long.

In addition, higher material buy-to-fly ratio aligns with recent sustainability and green credentials alongside manufacturers’ profits. FabricOptimizer enables the operator to nest around the defects, avoiding cutting defected plies that would require recuts and rework. The ‘nesting around defects’ solution supports the commonly used formats and systems and can be easily implemented.

The new easy-to-use simulation tool is embedded as part of Plataine’s FabricOptimizer solution, enabling manufacturers to take existing stock into account and avoid unnecessary waste when purchasing expensive materials. This tool enables faster response to bids and displays recommendations for material planning and procurement. With AI-based technology, users can test out a variety of input details, such as various roll widths or different quantities of kits to ensure the best yield and get recommendations on which material should be ordered for each kit, or number of kits. The simulation tool also saves operators’ time by automatically selecting different options and material quantities to create the most optimized cut plan for specific kits. All these capabilities are unique in the market and allow Aerospace manufacturers to produce more parts from existing material inventory.

Anat Kanner-Kalka, Director of Product Management at Plataine, says: “We are excited to unveil the latest enhancements to our FabricOptimizer AI-based offering. Material order lead time requires manufacturers to maximize their current stock. The easy-to-use simulation tool and ‘nesting around defects’ further meets the needs of our customers for dynamic solutions that improve the ordering process, reduce waste, and enhance efficiency. As FabricOptimizer evolves, we will continue to meet the needs of forward-thinking manufacturers and help them ramp-up production rates.”

About Plataine

Plataine is the leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing. Plataine’s solutions provide intelligent, connected Digital Assistants for production floor management and staff, empowering manufacturers to make optimized decisions in real-time, every time. Plataine’s patent-protected technologies are used by leading manufacturers worldwide, including Airbus, GE, IAI, Triumph, MRAS (an ST Engineering company), Alestis, Kineco-Kaman, IFS, Light & Strong, Kanfit and Ethan Allen. Plataine partners with SAP, Siemens PLM the Advanced Manufacturing Research Centre (AMRC) with Boeing, and CTC GmbH (an Airbus Company), and is also a part of the UK National Composites Centre (NCC) membership network, to advance the ‘Factory of the Future’ worldwide. For this work, Plataine has received Frost & Sullivan’s 2021 Global Technology Innovation Leadership Award for its AI-Based Digital Assistants for Manufacturing and Innovation Awards from the JEC, Plataine Receives SME 2021 Excellence in Composites Manufacturing Award and CompositesUK organizations. Plataine is ISO 27001 certified for compliance with information security management requirements. For more information, visit: http://www.plataine.com.