JEC World, Paris, France, April 25th 2023

Plataine, a leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing, announces its latest release of its Production Scheduler Solution. These advanced tools and algorithms provide composite parts manufacturers with a dynamic approach to production planning, considering all relevant elements including human capacity, tool availability and autoclave optimization, to automatically generate optimized manufacturing schedules.

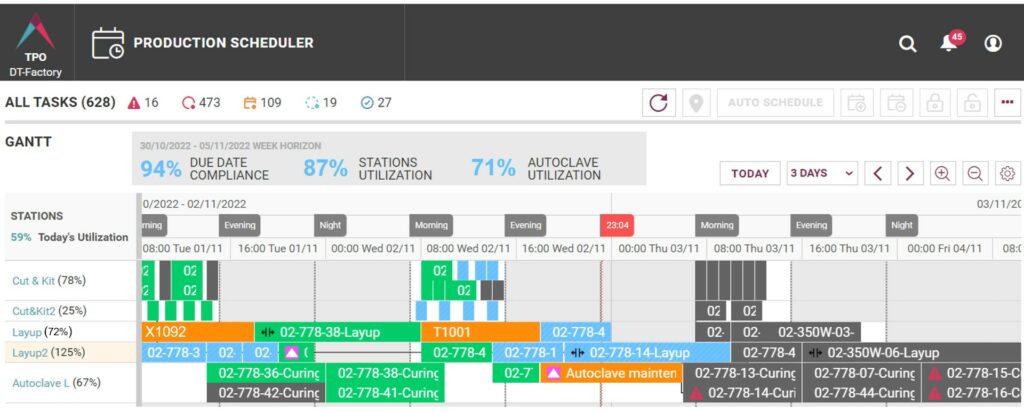

Plataine’s Production Scheduler is an intelligent and intuitive solution that presents new advancements and features to further maximize capacity while considering human resources, tools and machine constraints. The ability to handle resource capacity is an essential feature of the new Scheduler version, which enables the system to generate optimal plans while considering the availability of human and other factory resources. With the Production Scheduler, manufacturers can utilize their workforce efficiently while creating an optimized and feasible schedule. The tool support feature enables manufacturers to schedule and manage their tools, molds and resources effectively, ensuring that they are always in top condition and ready for use. The maintenance cycle monitoring ensures that tools and machines are properly maintained, reducing downtime and increasing productivity. The new UX design is user-friendly and intuitive, making it easier for planners to navigate and use the system effectively.

Plataine’s Scheduler overcomes bottlenecks in the production process, such as autoclave availability, and offers solutions to optimize production and autoclave runs. The Production Scheduler generates real-time reports that provide insights into the production process, enabling manufacturers to make data-driven decisions.

The Production Scheduler solution can quickly respond to unexpected events on the factory floor such as production delays, machine malfunction or shortage of staff. The automated solution may reduce response time to an incident from days to minutes – the planner can adjust the schedule, approve it with the supervisor and distribute it to the floor in a few mouse clicks. This leads to higher throughput and improved on-time delivery rate.

“Plataine’s Production Scheduler Solution is an industry game-changer. With its advanced Practimum Optimum™ algorithm, manufacturers can optimize their production processes, enhance productivity, and reduce costs,” said Amir Ben-Assa, VP Marketing & Product Strategy at Plataine. “Our solution provides real-time insight into production processes, allowing manufacturers to identify bottlenecks and quickly respond to unexpected events on the factory floor. With this solution in hand, manufacturers can ramp-up production and meet their targets.”

Further information could be found in this webinar featuring a real-life case study.

About Plataine

Plataine is the leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing. Plataine’s solutions provide intelligent, connected Digital Assistants for production floor management and staff, empowering manufacturers to make optimized decisions in real-time, every time. Plataine’s patent-protected technologies are used by leading manufacturers worldwide, including Airbus, IAI, Triumph, MRAS (an ST Engineering company), Alestis, Kineco-Kaman, IFS, Light & Strong, Kanfit and Ethan Allen. Plataine partners with SAP, Siemens PLM the Advanced Manufacturing Research Centre (AMRC) with Boeing, and CTC GmbH (an Airbus Company), NIAR (The US National Institute of Aviation Research) and is also a part of the UK National Composites Centre (NCC) membership network, to advance the ‘Factory of the Future’ worldwide. For this work, Plataine has received Frost & Sullivan’s 2021 Global Technology Innovation Leadership Award for its AI-Based Digital Assistants for Manufacturing and Innovation Awards from the JEC, Plataine Receives SME 2021 Excellence in Composites Manufacturing Award and CompositesUK organizations. Plataine is ISO 27001 certified for compliance with information security management requirements. For more information, visit: http://www.plataine.com.