Every new year brings hope, goals, and attempts to predict the upcoming trends that will set the tone for the industry. Looking back at the previous year in order to spot upcoming trends and prepare for them is incredibly important. It allows us to create budgets and business plans that take into account the innovations and mindset that’ll help our business to grow more efficiently.

For manufacturers, doing so is particularly crucial, as it might take some time to implement such plans within the organization.

The manufacturing industry is currently facing the exciting stage of the Fourth Industrial Revolution (Industry 4.0). This revolution is focused on embracing new digital tools and leveraging data behind each process with the help of AI technologies, to help improve efficiency and quality.

I believe that the massive transformation we’re only beginning to experience will be influenced by the following prominent technologies and approaches, some of which we are already familiar with, and others that are set to emerge in 2019.

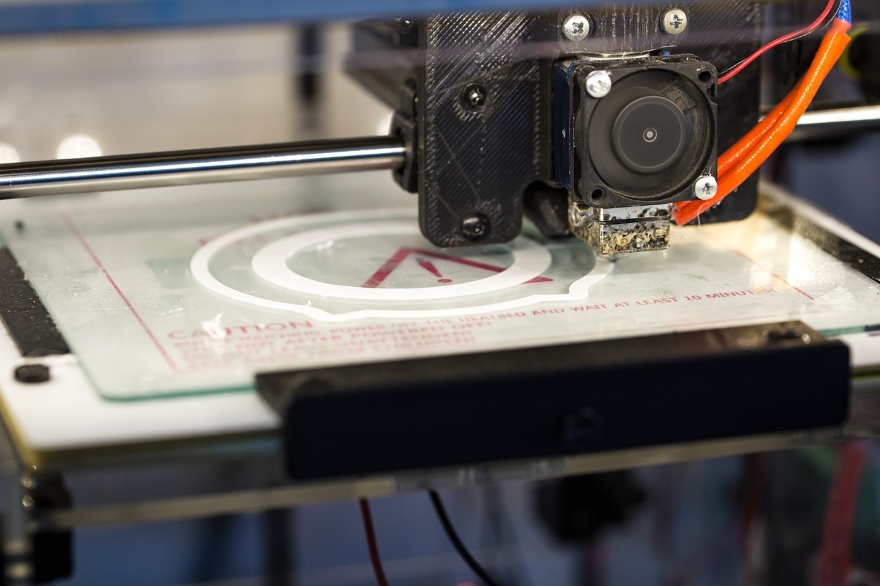

1. The Fine Print: Next-Level 3D Printing and Additive Manufacturing

3D printing is nothing new, but the many ways our industry uses it seems to change. This technology is turning from a prototyping technology into a significant part of mass manufacturing processes. Over 60% of US manufacturers have already announced their plans to use 3D printing, and thanks to lower printer prices and improvements in speed and accuracy, they will likely be able to follow through.

Instead of just prototypes, we can expect to see printed production parts (including metals) replace traditional production techniques, which should help manufacturers keep up with growing demands in a timely fashion.

2. Industrial Block-chain technologies and Cyber-security

Cryptocurrencies have been on quite the roller-coaster this past year, and trying to keep up with the ups and downs of this trend have made us all dizzy and skeptical. But this behavior is nothing strange when it comes to creating such a disruptive shift in the ways of the world. We may count on 2019 to have some crypto action as well, including within the manufacturing industry. The security aspects of block-chain offer a new level of accountability that will help the manufacturing industry gain some much-needed trust. The rise of cyber attacks against manufacturers calls for an innovative approach, and cloud security and block-chain may take an important role as early as 2019.

3. Not so Artificial: AI Offers Real value

AI is the technology everyone’s excited about, and with so many new ways to harness it, we are only scratching the surface of what it can offer manufacturers. A recommendation that is based on deeper insight into every step of the manufacturing process allows us to save money, time, and production costs. With AI-based optimization, gone are the days of late work orders, last-minute machine maintenance issues, endless wasted materials and resources, and unanswered order demands.

Combining the needs of the manufacturing industry with the capabilities of AI creates a layer of predictions that trigger actionable insights. These insights not only shed light on expensive and crucial blind-spots but also suggest immediate actions that can be taken for the sake of optimization.

Check out this use case of Smart-Thermocouples to better understand the potential of AI in manufacturing

In 2019 we can expect to see manufacturers put AI-based manufacturing optimization solutions to better use, and the more they experience the transformative power it entails, the more AI will become the manufacturers’ best friend.

4. The rise of the robots: Robotics & Automation

Say hello to my little friend! Robots are about to create interest among manufacturers, as they get smaller, cheaper, more sophisticated, and far more collaborative. So collaborative, that they are now being referred to as “Cobots”. Robots have the potential to change the face of industrial manufacturing as we know it. In the next 5 years, the market is set to invest $71 billion in industrial robotics, compared to about half the sum in previous years. Robotics and other automation tools will be embedded in pretty much every part of the manufacturing process, creating more integration-focused businesses that offer robotics-as-a-service solutions.

Not everyone is happy with this trend. Shop floor workers are often intimidated by the robotic trend, fearing that their jobs will be taken away. But, we’ve recently shared our 2 cents about this topic, uncovering what we believe will happen to the future manufacturing workforce. Spoiler alert: we offer an optimistic point of view.

5. Meet Your Future Employees: Professional Experts

Contrary to popular conspiracy theories, robots are not going to take your job. They are, however, set to change the way you do your job. In fact, each and every one of the trends listed in this article will require professional experts to create, implement, and use it on a daily basis, thus forming new job descriptions and opportunities for everyone involved. The skill set of 2019 is going to be exciting. For manufacturers, this will have a major impact on HR plans and professional training, as well as the tools that the experts of the future will have to work with. After all, preparing for the future means taking into consideration the demands of customers and employees alike.

6. The Fantastic Five: Introducing 5G

The manufacturing industry has been preparing for 5G to come into fruition for quite some time. In 2019, the promise of faster connections, latency improvements, and better control over IoT solutions may become a reality. Other technologies listed here, such as robotics and automation, rely on 5G for proper activation and control. By boosting the devices we all work with on a daily basis, such as mobile phones and wearables, 5G will help manufacturers better communicate their needs and the needs of their customers across the chain.

Early predictions suggest that manufacturing firms that use 5G could see as much as a 1% increase in overall productivity. (source)

7. Twin Peaks: Embracing The Digital Twin

Creating a digital replica of physical procedures is an interesting concept for manufacturers. Creating a digital twin means simulating a physical object in the digital world (imagine having your own hologram, where you can run experiments on it rather than on your own body). Incorporating the digital twins and their historical manufacturing details creates the ‘Digital Thread’. This recording of data enables the improvement of quality control and production agility at all times.

This helps predict the behavior of different parts and create dedicated solutions in advance. We’ve seen digital twins and digital thread in action in 2018, and in 2019 this approach may become more sophisticated and popular among manufacturers. Preparing for extreme conditions and demands will help improve the productivity of manufacturing logistics, allowing factories to navigate complex situations before they get dangerously complicated.

To better understand the essence of the ‘digital twin’ technology – read this Forbes article (from 2017).

8. The Headset Mindset: Wearables, AR, and VR

Once again, this is a trend that might not emerge in 2019, but will definitely improve and grow significantly. While wearables didn’t become a success in the consumer electronics market, they do present solid use cases in the industrial one. Wearable technology such as smart glasses adds another layer of productivity to manufacturing workers’ jobs, enabling them to do more without leaving the factory floor while keeping their hands free.

In 2019 we are more likely to see workers wearing smart AR and VR gear that will alert them and help them communicate better with colleagues.

9. High demand for on-demand

Preparing in advance is great, but being able to cater to customers’ needs in real-time is even better. The on-demand economy changes so many aspects of our lives, it only makes sense for it to transform manufacturing in 2019. This will prevent manufacturers from being left with unused stocks and materials, while at the same time allowing them to adhere to the latest customers’ needs and mood swings with smart micro-manufacturing. The machine-as-a-service approach is more than a technology trend – it is a new point of view. Watch our video that demonstrates how the future will be based on ‘demand manufacturing’

Summary

Predicting the future of technology is an interesting and complicated task. But when we step back and look at the big picture, we begin to identify certain patterns that are very telling. Taking a break from the task at hand to do so allows us to perform each task a little better. Whether we like it or not, the wheels of innovation are always in motion. As we encounter the above trends in 2019, we’ll be able to recognize them and appreciate what they can do to make us smarter and more efficient manufacturers. Together as an industry, we can harness these technologies to build operations that are better than ever.