The new version provides advanced AI-based algorithms and enhancements to optimize production plans, increase throughput, reduce waste, and improve on time delivery

Petach Tikva, Israel, June 10, 2020 – Plataine, a leading provider of Industrial IoT (IIoT) and AI-based software for manufacturing optimization, announced today the release of version 4.0 of its advanced cloud-based production scheduling application. Production Scheduler is part of Plataine’s TPO (Total Production Optimization) suite of applications, integrating production scheduling with managing shop-floor operations, and optimizing all other production resources such as materials, equipment and tools.

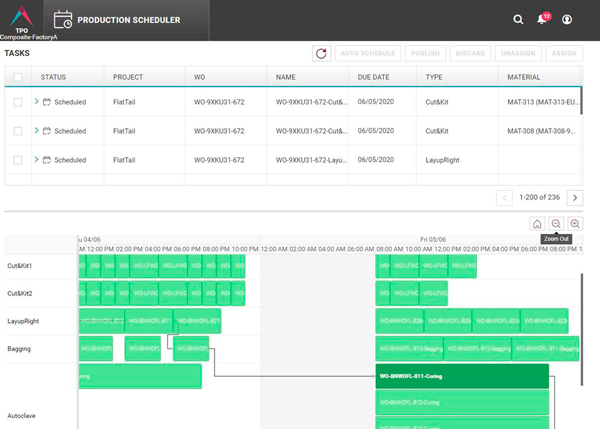

Traditionally, planning departments use assumptions and historical data to assess capacity and then assign tasks to resources and stations. Using Plataine’s Production Scheduler, planners now have a new, automated way to optimally schedule work orders optimizing production operations according to set business KPIs. The scheduling application acts as a digital assistant helping the planner to reach an optimal schedule quickly. The system then monitors actual production progress and compares planned vs. actual, to continuously adapt the schedule, reacting in real time to unexpected events such as incoming rush orders, machine malfunctions and production delays.

Plataine’s Production Scheduler uses AI-based technologies to generate an optimal schedule while leveraging historical and real-time data, bottleneck prediction, equipment efficiency and expected duration for tasks, to continuously improve the schedule.

Plataine’s Production Scheduler is part of Plataine’s TPO (Total Production Optimization) solution suite. TPO offers Industry 4.0 solutions to solve production challenges, by utilizing Plataine’s Digital Assistants, delivering smart alerts and recommendations in real-time to digitize, automate and optimize complex manufacturing processes. Production Scheduler is seamlessly integrated with the other TPO suite applications such as Material & Asset Tracker, WIP Optimizer and Tool Manager, to offer optimized scheduling decisions based on a rich digital tread.

Walter Ofer Abramsohn, Head of Product Management at Plataine: “Plataine’s Production Scheduler serves as a powerful Digital Assistant to planners and shop-floor employees by automatically prioritizing and scheduling each and every task and aspect needed to complete a work order, from raw material to a ‘ready to ship’ product. This cloud based always-available always-on solution, allows Plataine’s customers to benefit from the most advanced AI-based technologies and maximize operational efficiency”.

Avner Ben-Bassat, President and CEO of Plataine, adds: “Optimized production scheduling has a major impact on any organization’s productivity and profitability. I am excited about Plataine’s new Production Scheduler’s release, part of Plataine’s Total Production Optimization suite, packed with the latest AI capabilities, and seamless integration with the production floor to ensure real-time optimization.”

About Plataine

Plataine is the leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing. Plataine’s solutions provide intelligent, connected Digital Assistants for production floor management and staff, empowering manufacturers to make optimized decisions in real-time, every time. Plataine’s patent-protected technologies are used by leading manufacturers worldwide, including Airbus, GE, Renault F1® Team, Stelia North America, Muskogee Technology, IAI, Triumph, General Atomics, TPI Composites and Ethan Allen. Plataine partners with Siemens PLM, McKinsey & Company, VIRTEK, the AMRC with Boeing, and CTC GmbH (an Airbus Company), and is also a part of the National Composites Centre (NCC) membership network, to advance the ‘Factory of the Future’ worldwide. For this work, Plataine has received a Leadership Award from Frost & Sullivan and Innovation Awards from the JEC and CompositesUK organizations, as well as the Shanghai Society of Aeronautics (SSA). Plataine is ISO 27001 certified for compliance with information security management requirements. For more information, visit: www.plataine.com