Self-learning algorithm achieves unprecedented levels of optimized KPIs and schedule practicalization

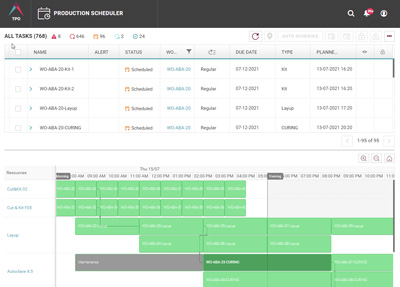

Waltham, MA, July 15th, 2021 – Plataine, a leading provider of Industrial IoT (IIoT) and AI-based software for manufacturing optimization, announced today the release of Practimum-OptimumTM: a breakthrough AI algorithm for optimizing production scheduling, which takes manufacturing planning and scheduling to the next level by combining unprecedented levels of optimized KPIs with a practical, robust planning application. Plataine’s Production Scheduler is part of Plataine’s TPO (Total Production Optimization), cloud-based suite of interconnected applications, integrating production scheduling with shop-floor operations management, while optimizing all production resources such as materials, equipment and tools.

Most existing software solutions for scheduling utilize a search algorithm to optimize top level KPI goals of the overall schedule such as due-date compliance, production throughput or machine utilization. However, once such an optimal schedule is generated, the users often detect individual assignments that fail to address specific customer priorities, executability considerations, or other practical matters. This leads them to make changes in these assignments and adjust the schedule manually.. These changes would make perfect business sense even if they led to lower KPI scores but require constant human involvement in the process. Plataine’s patent-pending Practimum-OptimumTM algorithm, driving the production scheduler, builds optimal schedules that already integrate practical considerations and supports the user in further integrating subjective judgment changes.

The Practimum-OptimumTM algorithm includes an AI-based core that automatically generates large datasets of a wide variety of schedules within the schedule’s universe of the factory. With its built-in machine learning algorithms, the Practimum-OptimumTM Scheduler teaches itself deep insights of the schedules’ universe including the trade-offs between competing goals, clusters of similar schedules, patterns of demand sets, and best attainable values for each individual KPI score. Historical schedules are not mandatory, though they are very useful when available. These insights are used by the Practimum-OptimumTM algorithm to produce schedules that are both optimal and practical to execute. Production planners can set target values for any mix of business goals such as on-time delivery, overall equipment efficiency (OEE), or make-span, and the Practimum-OptimumTM Scheduler algorithm will produce the best practical schedule that is the closest to these targets, including a visual interactive Gantt chart and graphic indicators.

Plataine’s intelligent Digital Assistants accompany the users throughout schedule execution, alerting them to deviations in the planned schedule, such as a task that is taking longer than planned, and offering recommendations and insights before a crisis occurs. Over time, as the algorithm is being used and real-life schedules are generated, the learning algorithm adapts its planning capabilities and improves its performance.

Avner Ben-Bassat, President and CEO of Plataine, adds: “Production scheduling has a significant impact on the productivity and efficiency of each organization. Our Practimum-OptimumTM Scheduler represents a paradigm shift in schedule optimization applications that are not only mathematically optimal, but also self-learning and practical to execute. I am confident that this latest development of optimized schedules will improve the bottom line of our customers’ business”.

Walter Ofer Abramsohn, Head of Product Management at Plataine: “This breakthrough innovation of Plataine’s cloud-based Production Scheduler brings new optimization capabilities for production planners, helping to generate optimal and practical schedules that reach their targets. Our intelligent and connected Digital Assistants help planners and shop-floor employees automatically prioritize and schedule every task needed to complete a work order, from raw material to a ready to ship product.”

Plataine’s TPO suite offers Industry 4.0 solutions to solve production challenges, including Material & Asset Tracker, WIP Optimizer and Tool Manager applications, to offer optimized scheduling decisions based on a rich digital thread.

About Plataine:

Plataine is the leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing. Plataine’s solutions provide intelligent, connected Digital Assistants for production floor management and staff, empowering manufacturers to make optimized decisions in real-time, every time. Plataine’s patent-protected technologies are used by leading manufacturers worldwide, including Airbus, IAI, Triumph, Renault F1® Team, Stelia North America, Alestis, Enercon, Century Furniture, Muskogee Technology, and Ethan Allen.

Plataine partners with SAP, Siemens PLM the Advanced Manufacturing Research Centre (AMRC) with Boeing, and CTC GmbH (an Airbus Company), and is also a part of the UK National Composites Centre (NCC) membership network, to advance the ‘Factory of the Future’ worldwide. For this work, Plataine has received a Leadership Award from Frost & Sullivan and Innovation Awards from the JEC and CompositesUK organizations. Plataine is ISO 27001 certified for compliance with information security management requirements.

For more information, visit: www.plataine.com.