This article provides highlights from our ‘2022 trends in global manufacturing – industry survey’ . Download the complete report here.

Today, digital transformation plays an integral role in any manufacturing business strategy, to translate investments into tangible results at the enterprise level. The past 2 years accelerated fundamental changes to how manufacturers interact with legacy enterprise systems (such as MES) to maintain business continuity, improve agility and increase responsiveness to market fluctuations.

According to this 2022 SME unique industry survey, factory floors are managing to properly collect sufficient data and to use advanced analytics methods to improve operational efficiency.

This article sheds light over some of the trends revealed in the report. For a comprehensive exploration, download the report here.

C-level executives: smart manufacturing initiatives have a high adoption rate

Today, the shift towards digitalization and automation is progressively taking hold to improve products and processes, increase efficiency and productivity, reduce operational costs, and increase customer satisfaction.

More than 70% pointed out the overall importance of improving on-time delivery, lowering production costs, minimizing production delays and reducing quality risks. Comparing to the 2018 survey, manufacturers have shifted priorities to make room for agility, efficiency and cost savings.

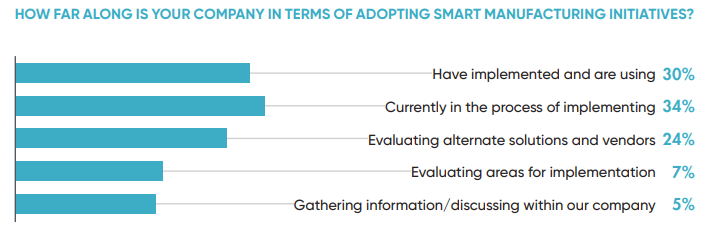

64% of the respondents have already implemented (or are in the process of implementing) smart manufacturing initiatives, while less than 36% reported that the company is only just now evaluating and discussing the desired solution.

Those findings are in line with findings from a recent survey conducted by PWC, according to which 91% of industrial companies are already investing in digital factories, with clear goals and ROI expectations for the next 5 years. Increasingly, businesses understand that this is a marathon, not a sprint, and are willing to work hard and put in the time.

Real-time analytics take the lead

Repetitive, time-consuming tasks lead to human error. By automatically collecting granular data, manufacturers are better able to measure, understand, and optimize production without suffering from data insert errors and overloading on the workforce.

Forrester recently discussed the fact that the pandemic’s wake drives automation trends, meant to “gain the ability to reshuffle priorities on a dime by using the latest analytics”.

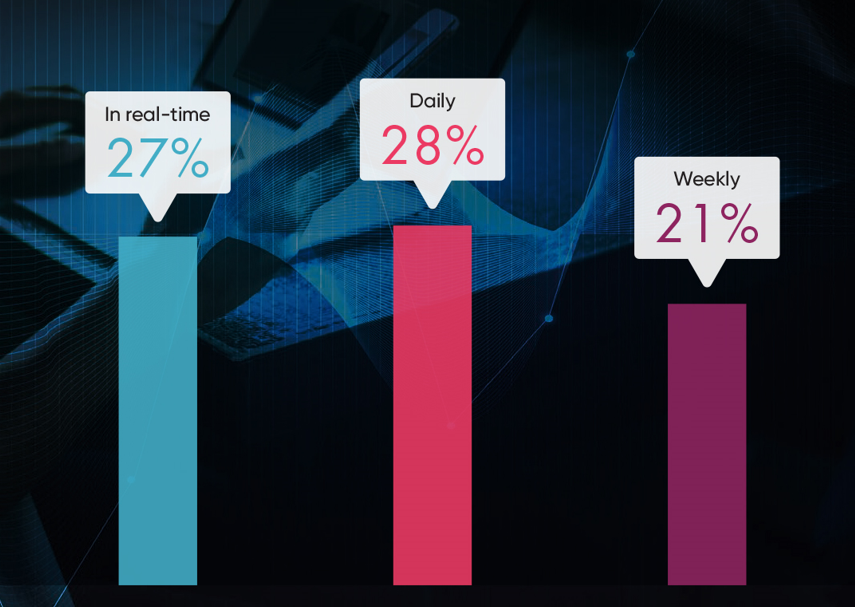

Back to our survey, 27% of respondents collect factory floor data in real-time, while 28% collect data daily and 21% collect data weekly. With only 27% reviewing the data in real-time, this presents a big opportunity for real-time analytics; the industry’s goal should be to close this gap allowing manufacturers to improve their operations, boost productivity and increase quality, and this is only part of the potential that real-time analytics holds.

For instance, by leveraging real-time data generated from IIoT sensors and legacy software, AI layers can predict how likely a machine or a tool will need maintenance in any given time. Once the likelihood surpasses a predetermined threshold, the system automatically triggers an alert in real-time and offers concrete recommendations on what to do next (e.g. direct the work order to a different workstation, change the shift schedule or alike).

Smart manufacturing can offer manufacturers a great return on investment (ROI). Over 70% responded 2 times or higher return on investment in the first 6 months. This clearly shows that investing in AI, IIOT among other Industry 4.0 technologies is essential.

Additional topics discussed in the report include main factory floor challenges, priorities for industry 4.0 investments, and more…

Click to download the full survey report here: