We’ve recently discussed the missing elements of MES software that are essential for extreme automation and cost savings and are added via implementing AI based industry 4.0 addons. In short, AI enrichment is a must in order to move MES from registering data towards running predictions, using predictions to provoke alerts with actionable insights and allow extreme (nearly 100%) automation.

With the aerospace composites market expected to reach USD 63.37 Billion by 2027, there is certainly an incentive to find solutions that can push operations cost effectiveness up while reducing related risks.

What’s the gain of adding AI? Here are just a few examples:

- Composites related manufacturers use AI layers to coordinate between the freezers and the autoclaves, and defrost just the right amount of composite material that is needed to meet the deadlines. This minimizes material waste and saves employees the overhead of manually coordinating between demand, deadlines, autoclaves availability, and supply chain factors.

- AI is used to maximize autoclave throughput, saving energy while increasing their utilization rates.

- AI layers identify and alert on deviations from specific patterns such as misplacements, or “out of sequence” cases saving time on searching for tools across the factory floor.

- AI predicts issues with specific workstations, materials about to expire, machines or tools that must go into maintenance and alike, and alerts with specific instructions on the steps needed to be taken ahead. This results in minimized rework meaning getting all jobs right on the first go.

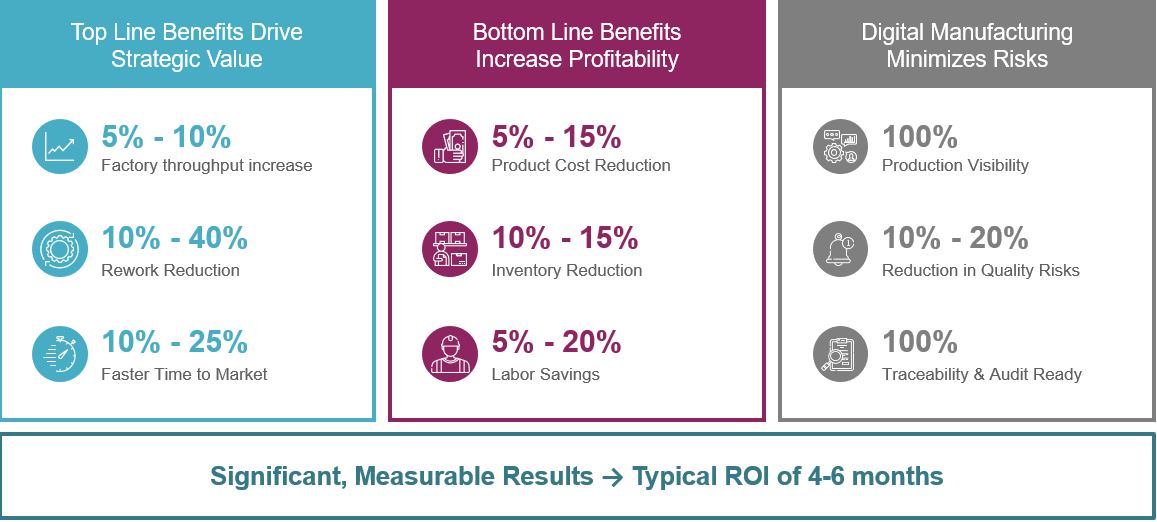

The benchmarks below demonstrate the monetary contribution of smart Industry 4.0 solutions that are built on AI solutions for manufacturing (such as Plataine):

The story of Light & Strong

Light & Strong is a leading composite parts manufacturer established by a team of composite material experts that was recently acquired by Lohia Group. The company specializes in production of aerospace and military carbon-fiber and glass-fiber composite components.

The company assists customers through all stages of the manufacturing process, from planning and development to production of tools and molds to prototyping and mass production.

The production team was constantly searching for new levers of process automation in order to reduce material waste, improve quality control, and offer real-time visibility across production lines so issues could be tackled before they arose.

Due to the global labor shortage, the company was keen to automate any processes that could be automated to free up factory staff for higher value tasks.

During this time, the company’s management decided to further explore AI-based IIoT technologies and the implementation of advanced Industry 4.0 layers on top of its MES solution.

Light & Strong deployed Plataine’s AI and IIoT based software aiming to see significant reductions in material waste, as well as improved quality assurance and faster production times:

Initial results and expectations for the future:

One of the key benefits gained by adding an AI-layer and extreme automation capabilities is a significant reduction in material waste and rework, due to automated management of freezer-stored composite raw material.

- When material rolls arrive at the factory, they are tagged with RFID sensors that provide a real-time record of the material’s location.

- The most appropriate raw material is assigned for each job by the software, taking into consideration exposure time and expirations dates, as well as remnant utilization. Cutting plans are automatically created based on the dynamic, multi part strategy needed for the production.

- The staff no longer need to spend significant time manually calculating and reporting shelf-life, eliminating the possibility of human error and freeing employees up for higher value and less repetitive tasks.

- The addition of a real-time visibility layer across the production floor (via a live map that tracks the raw materials) helps production managers identify and resolve upcoming issues before they disrupt or delay production.

- An ever-going analysis of the production schedule to spot opportunities to use up material remnants enables further optimization of material yield – and it has the capability to manage thousands of production jobs at a time if needed.

- Additionally, a Digital Thread is maintained. This is a fully digital record of the entire production process. This means that if a material batch is later found to have been defective, it is possible to instantly identify which kits were affected and remove them from production, slashing the cost of poor quality (COPQ) and ensuring they are always audit-ready.

The automation of inventory management, as well as material condition monitoring, minimizes human error and frees up the valuable time of skilled workers for other production tasks.

Full visibility of all available material rolls, including their defrosting status, and the exposure time left (ETL) on each roll or remnant, as well as of all production variables on the shop floor. Due to this visibility, you can automatically calculate ‘in and out’ of freezer times and select the most appropriate material for the job.

Read the full Light and strong case stud