In this article, we will explore what Industry 4.0 is, the advantages of a connected factory, successful implementation of a connected factory, and the future of manufacturing with the help of Industry 4.0 and the connected factory.

What is Industry 4.0?

Industry 4.0 is the fourth industrial revolution, which focuses on automation, data exchange, and connectivity in manufacturing. Industry 4.0 uses cyber-physical systems, the internet of things (IoT), cloud computing, and cognitive computing to create a smart and connected factory. This means that machines, systems, and products can communicate with each other, resulting in more efficient and productive manufacturing processes.

According to a report by Deloitte, Industry 4.0 is transforming the manufacturing industry by enabling improved operations. In the “plan,” “source,” and “make” stages of the value chain, various physical-to-digital and digital-to-physical connections can transform planning, support, and factory operations.

Advantages of a Connected Factory

The implementation of a connected factory has several advantages, including improved efficiency, reduced downtime, and increased productivity.

One of the main advantages of a connected factory is improved efficiency. The integration of IoT sensors in machines and systems allows for real-time monitoring and analysis of production processes. This means that factories can identify issues and resolve them quickly, leading to less downtime and improved efficiency.

Another advantage of a connected factory is reduced downtime. With real-time monitoring and predictive maintenance, factories can detect and address potential issues before they become major problems. This means that factories can reduce downtime and avoid costly repairs.

Connected factories also increase productivity by providing valuable insights into the production process. With the help of data analytics, factories can identify areas that need improvement and optimize their production processes. This can lead to increased output, reduced waste, and improved quality.

Successful Implementation of a Connected Factory

While the benefits of a connected factory are clear, implementing the necessary technology and infrastructure can be a complex task. To successfully implement a connected factory, manufacturers need to consider several factors, such as connectivity, data security, and the integration of various systems.

Connectivity is a crucial aspect of a connected factory. Manufacturers need to ensure that all machines and devices can communicate with each other seamlessly. This requires a robust and reliable network infrastructure that can handle large volumes of data in real-time. Implementing wireless connectivity, such as Wi-Fi or 5G, can help achieve this goal.

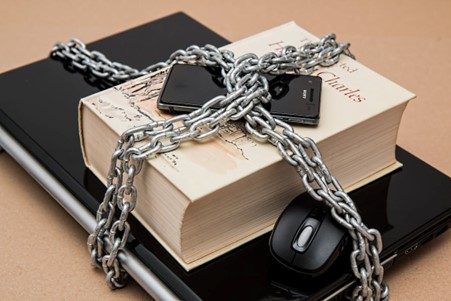

Data security is another critical consideration. A connected factory generates a massive amount of data that needs to be collected, analyzed, and shared. This data contains valuable information about the manufacturing process, production line performance, and product quality. However, it also presents a significant security risk. Manufacturers need to ensure that their data is protected against cyber-attacks, data breaches, and other security threats. This requires implementing robust cybersecurity measures, such as firewalls, intrusion detection systems, and data encryption.

Integrating various systems is another challenge when implementing a connected factory. Manufacturers often have a diverse range of equipment and systems in their factories, such as ERP, MES, SCADA, and PLC systems. Integrating these systems into a single, cohesive platform can be a daunting task. However, it is essential for achieving the full benefits of a connected factory. A unified platform can provide real-time visibility into the entire manufacturing process, allowing manufacturers to identify and address issues quickly and efficiently.

The Future of Manufacturing: Leveraging Industry 4.0 and the Connected Factory

The future of manufacturing looks bright with the help of Industry 4.0 and the connected factory. According to a recent report by MarketsandMarkets, the connected manufacturing market is expected to grow from $20.7 billion in 2020 to $37.8 billion by 2026.

One of the main trends that we can expect to see in the future of manufacturing is the increased use of artificial intelligence (AI) and machine learning (ML). AI and ML can help factories analyze data and predict potential issues, which can help factories operate more efficiently and reduce downtime.

Another trend we can expect to see in the future of manufacturing is the increased use of robotics and automation. With the help of Industry 4.0, factories can use robotics and automation to handle repetitive tasks and improve production efficiency. This can also help reduce the risk of human error and improve safety in the factory.

In addition, the future of manufacturing will also see a greater focus on sustainability. With the help of Industry 4.0, factories can reduce waste and energy consumption, leading to a more sustainable manufacturing process. This will be an important focus for manufacturers in the coming years as consumers become more environmentally conscious and demand more sustainable products.

Conclusion

The integration of Industry 4.0 and connected factory technology has transformed the manufacturing industry, bringing about significant improvements in efficiency, productivity, and quality. The implementation of a connected factory requires careful planning and a well-thought-out strategy, but the benefits are undeniable.

As we look to the future of manufacturing, we can expect to see increased use of AI, ML, robotics, and automation, as well as a greater focus on sustainability. Manufacturers who embrace these trends and continue to innovate will be best positioned to succeed in the rapidly evolving manufacturing industry.