As a solid ecosystem, many of us in the Manufacturing arena were part of a growing economy, knowing that the products we provided were of real value and a necessity to our customers (and their customers). The recent global events were unpredictable and no one could have imagined that the skies would be closed or that social distancing would be mandatory.

Enters the coronavirus crisis.

In what feels like a minute and an eternity all at the same time, the industry is now busy dealing with a rollercoaster of shifts that impacts everyone in every aspect of our lives, including factories shutting down in Europe; airlines requesting financial aid; the European automotive industry coming to a screeching halt; and other disturbing news in a wide range of fields that include Aerospace, Automotive, Heavy Machinery, and more.

The next paragraphs will examine some of these changes and the main strategies that come along and help manufacturers face today’s challenges, keep the resilience and prepare for the day after the crisis.

What in the world is going on?!

The manufacturing industry in Asia and particularly China seems to be nearly on the path to recovery in the past few weeks, and factories are gradually resuming production. China still faces challenges related to both local and global financial shifts, but we are beginning to see the light at the end of the tunnel, and the entire world is looking forward to it, too.

At the same time, it is also becoming increasingly clear that we will come out the other end significantly different since COVID19 is, clearly, a game-changing event. For instance, it is obvious that supply chain activity and market requirements will change for the shorter and longer-run.

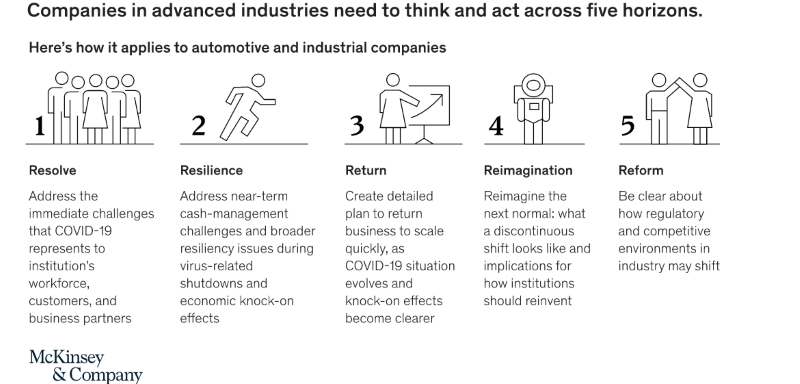

According to a report about COVID19 by McKinsey that was recently published, there are 5 stages to “how manufacturers should run the managing COVID19 crisis” process:

Well, I would like to turn the spotlight on stages 3 and up, in which the industry resumes activity and makes the necessary adjustments to meet the market needs of a changed world. These stages are coming, and we better be prepared.

Consider in assessing the situation and in planning the next steps:

- Like everything else, this too is temporary: Even those who are currently experiencing the crisis at its worst should bear in mind that it will eventually, and hopefully sooner than later be over. This means that businesses should not only hurry to focus on dealing with the here and now, but must also prepare ASAP for the changes that are just around the corner. Planning for the day after work is resumed should begin now in order to prevent further delays and costs. In the Automotive sector, for example, manufacturers should prepare for different plant closure lengths and set a strategy for each one, as well as consider changes in consumer demand and sentiment. European automotive manufacturers have experienced more extensive closures compared to Asian ones, which is likely to affect both future production capacity and sales.

- Shifting profit structures and developing compensation mechanisms: As soon as things start to pick up again, manufacturers will have to be even more aware of the ROI their efforts have to offer and recalculate their profitability structure. This means running ROI related activities with a whole new perspective this time. ROI-focused solutions and tactics have always been a must, but many manufacturing businesses will sense the impact of this approach in a stronger, more immediate way. There are ways to push profitability up, by deploying multiple strategies such as reducing waste and scarp, increasing OEE, automating processes and lowering inefficiencies. We’ve written endless articles and guides about these strategies. While in normal days, deploying new strategies takes time and thought, in such days, you may want to speed some of these processes up, in order to increase resilience in the upcoming months.

- Balancing the decrease in demand with utilization optimization: The forecasted lower demand, at least in the short run, will demand manufacturers to become more agile and efficient with the resources they currently onboard. Manufacturers will increase the use of utilization-oriented strategies and solutions. Under the new circumstances, some businesses will have more time to address these issues, and the optimized production will continue on as things go gradually back to normal over time.

PS: Read our professional guide on how to estimate the ROI of implementing AI based manufacturing optimization software:

- Managing an unstable demand:

Market needs and demands are likely to be volatile in the near future, as everyone is preparing for and experiencing the financial impact of the crisis. Many manufacturers will need to focus on the elements that make their products a necessity, but will also need to embrace creative solutions in terms of financial flexibility, innovative technology, and more, that is in the purpose of running demand forecasts, and real-time communication with their supply chains. - Leveraging innovation: Manufacturers will have to learn how to rely more on solutions involving Industry 4.0 technologies such as cloud computing, Artificial Intelligence (AI), and the Industrial Internet of Things (IoT), as these solutions can directly support agility and multi-aspect decision making under changing conditions, they know how to support smart supply chain collaboration, let alone their huge contribution to analyzing the productivity and cost-efficiency of manufacturers. With the shift in plants’ production force, managers will need tools to help them monitor every workstation remotely, make data-based decisions in real-time, and increase automation levels. In other words, now is hardly the time to run blind, or be outdated technologically.

If you are not sure how efficient and smart your factory really is, Use our ‘test yourself’ guide to run some estimations.

- Diversifying work methods: We’ve all been experiencing shifts in our everyday work. Some employees were unable to continue working at all, while others switched to remote employment and changed their routine accordingly. Chances are that upon our return to production, new methods and approaches will be examined in that aspect as well, partly as a necessity and partly as a natural evolution. This is especially true when considering the utilities while boosting the productivity of employees and allowing them to control some aspects remotely.

- More hygienic, less crowded factories: The coronavirus crisis highlighted the importance of workplace hygiene and formed new habits, some of which will last at least until a cure for the virus is found. This will also include automation solutions that minimize human interference (and support distancing) as much as possible, thus protecting workers from the contagious virus and a possible shut-down.

- Supply chain optimization: The crisis already revealed a disturbing truth regarding supply chain dependencies, and industrial businesses around the world are likely to examine their current state, draw dramatic conclusions, and take actions to increase their real time collaboration with supply chain partners, hence support their resilience. Those without a contingency plan will finally create one, and a boost in local production and supply will be felt across the industry.

As Mckinsey put it: ”Supply-chain leaders are placing more emphasis on forecasting efforts to help them determine global ramp-ups and improve reaction times. Going forward, we expect that local-to-local supply chains will provide more flexibility and that vendors will be more accommodating. We also expect that companies will increasingly adopt digital and analytical tools as they recognize the real value of predictive monitoring and supply/demand matching.”

- Alternative production lines: Being adaptive to changes is the basic pillar of evolution. We already witness factories that were modified to produce medical equipment, by leveraging additive manufacturing, computation and more. Ensuring there’s always a “plan B” ready for an alternative production to be quickly implemented in case of an immediate need, may not only be extremely important in COVID19 days, but as a lesson learned for the future.

Summary:

Saying that every crisis poses an opportunity may seem like a huge cliché right now, but as in many cases clichés are, it also happens to be true. Manufacturers are now enforced to create an out of box tactical recovery plan that will set their near future. History shows that the strongest players came out of crisis even stronger. Changes enforced them to take drastic actions that made them better.

What did they do? Well, they probably did all written above and more, but from a high-level perspective, they responded fast, they adapted their planning and operations they created and developed plans for every possible scenario and they kept moving, not stopping for a minute.