When a new year begins it’s time for us to create our annual trend list., While many of us feel that 2020 lasted an eternity, it’s still hard to believe that it’s almost over and we are still here, surviving to tell its story.

This past year was like nothing we’ve ever experienced in so many aspects. Some of the changes it brought will hopefully be over soon, while others are here to stay. The same is true for some of the trends we included in last year’s trends article; Processes like ‘supply chain optimization’, ‘improved data security’, and the importance and adoption of ‘automation’ are only increasing in.

Looking at these and other trends is important because it sets the tone for the years ahead and allows us to prepare as an industry. Even when a pandemic hits out of the blue, manufacturers who were relatively resilient and were already embracing the latest technologies, found it easier to adjust and respond. In an uncertain climate like today’s, the next lines offer a clear direction for prioritization and development.

So, what’s in store for manufacturers in 2021?

Planning a COVID-19 exit strategy: Oh, how we enjoy typing these words! It’s almost time to put those disaster recovery plans aside and replace them with concrete resilience strategies that will get many businesses back on track. That doesn’t mean that manufacturers have to get rid of every change created due to the pandemic. It’s best to measure and see which adjustments proved beneficial regardless of the pandemic, and keep them around.

- Employee health focus: Though we’re seeing light at the end of the tunnel, manufacturers shouldn’t take any unnecessary risks when it comes to employees’ health. New regulations are released on a regular basis, and it’s best to follow them closely. Procedures involving check-ups, social distancing, and reporting will still be a focal point, at least during the first half of the year. As we’ve quickly learned, health regulations and proactive related steps manage to reduce the impact of ‘regular’ winter diseases. Therefore we forecast that health regulations will be kept regardless of the vaccine.

Smart-factory trends

The need for a smart factory will be greater and more apparent in 2021. It will be manifested in the following ways:

- Remote operations using cloud technology: When #WFH (working from home) is one of the most popular hashtags, controlling the production line from afar was never this critical. In 2021, remote management goes to the next level with organized data, advanced automation, and innovative technologies like cloud based software providing complete visibility over production progress from any browser. Even when COVID-19 becomes a distant memory (and I doubt this will happen in the near future), we can expect factories to keep many of these capabilities to allow for more flexibility and better visibility, control and communication.

- Supply chain optimization: This has been a goal for manufacturers for quite some time, but now, facing the concrete demonstration of how supply chain challenges can be instantly amplified, this is becoming a priority. COVID-19 made manufacturers realize the risk involved in their current supply chain structure, causing almost 60% to make significant supply chain changes in order to reduce risks. The pandemic also taught manufacturers to be agile, and this agility should be related to the optimization of the supply chain in 2021. The agile supply chain should be strong enough to face market shifts in any direction. Supply Chain Management (SCM) technologies based on machine learning and AI will be able to not only prepare for any hypothetical event but also predict these events in advance.

- Data-empowered real-time decision-making: You can’t optimize your supply chain or production floor operations without data. Research finds that 90% of companies that deal with third-party logistics say that data-driven decision making promotes supply chain optimization. Pandemic or not, the manufacturing arena moves fast, and managers must make immediate decisions. Solutions that gather, analyze, and deliver actionable insights will enable companies to

make smart predictions under unstable conditions.

As data-driven, real-time, AI based manufacturing solutions present clear ROI, this trend is expected to exponentially increase.

Check out this guide to help you estimate the ROI in your factory:

- Personalization: Personalized products will result in a smaller manufacturing collection and on-demand purchasing that will replace large stocks and shipments. End customers will gain more control over the process and the end result, while manufacturers learn to give audiences a chance to express their minds and needs. Companies will shift some of their production line to allow for more customization and, in turn, gain better resource management.

- Workforce optimization: Many of the above trends require talent to plan and execute these new procedures. The manufacturing industry will need to track and train people if it wants to avoid being severely understaffed. Research shows that skill gaps hinder digital transformation procedures and manufacturers’ HR teams struggle to close this gap. Remote work technologies will be used to let experts quickly train shop floor employees on needed skills, and realign them super fast to be prepared for needs that may arise.

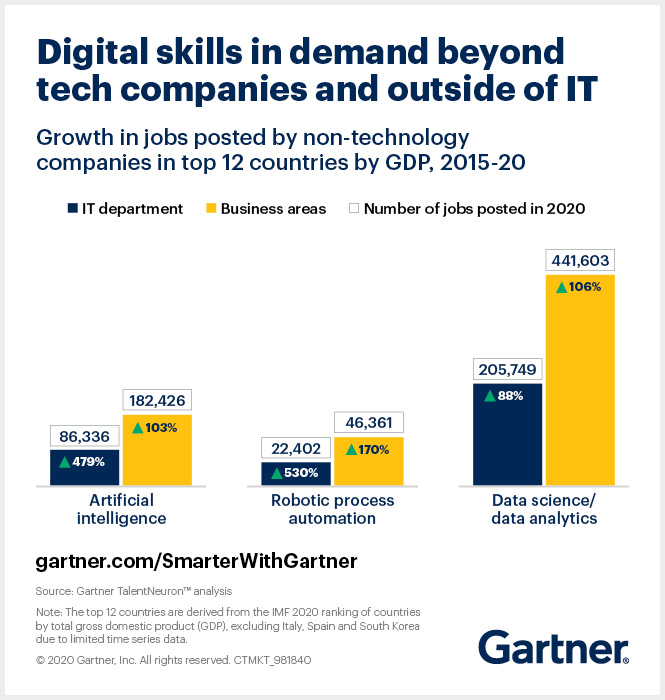

Source: gartner.com/SmarterWithGartner

- Nearshoring and reshoring: Lockdown and closed-borders caused huge delays in shipments, and hence in production. Manufacturers that were highly dependent on overseas inventory shipping suffered more. Manufacturers will therefore tend to choose to overcome several supply chain challenges and risks by bringing the production line closer. In July, 69% of US manufacturers were actively looking into reshoring options. Manufacturers’ production and distribution procedures will adjust accordingly, and the result will free companies from their dependency on distant inventory and offer better control and stability.

- 5G technology: This leap forward, that has already started, is expected to boost efficiency across the board, IIoT devices will deliver reduced latency, data centers will operate smoothly, AI solutions will have a bigger data capacity, and more. Just think of manufacturing – cobots that are highly dependent on zero latency. 5G technology and infrastructure are still being implemented in many regions, and in 2021, we’ll begin to see the impact of these technologies.

Summary

In 2019, we concluded the annual post by saying that changes in manufacturing take time. This year, we’ve had the opportunity to experience accelerated shifts that made room for new and exciting technology solutions.

Sure, these weren’t ideal circumstances, and the industry also dealt with significant setbacks, but the silver lining will be evident in many areas of the industrial world.

Here’s to a healthy, innovative 2021 and the many blessings it may bring us all.