Traditional nesting software has reached the limits of the efficiencies it can deliver at the product level. Manufacturers focused on continuous improvement of their production processes are now turning to more accurate metrics and a holistic approach to reduce additional waste in the nesting and cutting process.

The problem with focusing only on product level nesting yield (the total area of the parts in a product divided by the area of the material used for the nest) is that it can give an illusion of a higher yield in production. Whereas by measuring overall manufacturing yield, manufacturing companies can improve their actual overall material utilization, especially in manufacturing sites that produce multiple parts and quantities for their customers. Identifying inefficiencies in production, such as piling up and eventually discarding material remnants and short rolls, allows manufacturers to employ production optimization software to address previously hidden problems and create dynamic nests on the fly.

Optimizing the production process as a whole by taking into account actual stock available, warehouse space saved, and material efficiency can improve both manufacturing yield and nesting yield, while also delivering labor and other efficiencies that as a whole result in lower product prices and faster time to market.

Looking beyond traditional nesting solutions and metrics

Most traditional nesting software now tends to deliver fractions of yield improvement in relation to competitors because they are limited by design to nesting a given quantity of product on predefined material of specific length and width. This creates a glass ceiling of efficiency within the nesting product category that cannot calculate other relevant factors available, including product design, remnants stored in the warehouse, batch information for material, other incoming orders, or machine capability.

A ‘point solution’ can only go so far. It leaves shorter rolls in stock, often unused and ultimately discarded, wasting precious material and requiring additional labor. Manufacturers may feel they have taken the potential of nesting to its limit using software or human solutions, choosing instead to focus on other areas for continuous improvement. However, additional efficiencies are also available in areas such as the scheduling of similar products to be cut and the selection of raw material to be used (including remnant utilization).

Nesting yield vs manufacturing yield

Companies are already operating efficiently when it comes to nesting each individual product, but few of them look beyond product-level improvements. Nests are generally prepared once per product on a given roll size and stored for future use and reference. It is a holistic approach to the production process that can really deliver further savings.

Tracking material yield is an important metric but, by focusing on product level nesting yield and failing to fully calculate overall manufacturing yield, inefficiencies in the process remain hidden. This leads to material waste becoming accepted as an avoidable cost, failing to realize the true utilization of material in production. If single-product nesting yield is used as the primary metric, these inefficiencies can become a fixed (amortized) factor. It could be simply calculated into decisions relating to material consumption or costs, rather than as a problem to be addressed. On-site process studies suggest that the gap between the nesting yield and overall manufacturing yield typically ranges from 5% to 10%.

Overall manufacturing yield is a more accurate measurement. It reveals the total material that becomes finished product, as a percentage of the total raw material purchased by the plant. By calculating overall manufacturing yield during the nesting/cutting process, mindsets can be changed so that ‘hidden’ inefficiencies are identified and addressed, rather than overlooked as a ‘cost of doing business.’

Waste in production drives up costs, leading to over-priced products, over-costing of future contracts, excess purchase of raw material and negative impacts on other production processes. Calculating manufacturing yield and then using a dynamic, holistic approach to improve it that changes daily according to product mix, scheduling decisions and selection of raw material (including remnants) makes the best possible use of material and labor.

Utilizing remnants efficiently

The definition of remnants varies hugely across the industry (typically defined as being between 3-5 yards), and their reuse usually requires additional labor to manage and utilize them. Where remnants are used, the gap between the nesting yield and manufacturing yield will be narrowed accordingly. Looking at why remnants are not typically utilized often leads back to the nesting process and the CAD system in place. This is typically disconnected from production realities and variables such as order mix, material width, and material dye-lots/shade.

Using production optimization software to provide an integrated, dynamic approach to nesting delivers on-demand nests that take into account the remnants available. This allows a single product to be cut on multiple rolls of various sizes. Using software in this way saves tremendous amounts of labor and makes sure that optimal decisions are made every time. Substantial improvements to both nesting yield and manufacturing yield can also be made by fully integrating roll selection, cut planning, and nesting with other production processes such as ordering and production.

Taking holistic approach to the whole production process to reach overall operational excellence

It is the holistic approach to cutting and nesting provided by next-generation production optimization software that allows maximum efficiencies to be achieved in material, labor, and time. Dynamic cutting plans work with a range of factors to generate comprehensive production plans on the fly, delivering a whole new opportunity to save material, and smash through the glass ceiling of potential efficiency savings.

Employing creative optimization techniques using this ‘enterprise level’ solution not only benefits nesting yield and manufacturing yield but also first pass yield. Addressing nesting and cutting challenges methodically and efficiently requires a dynamic and integrated optimization approach that sees close collaboration between all teams involved (engineering, manufacturing, procurement etc.) and bridging the gaps between the various systems deployed (such as CAD, ERP, PLM).

Where nesting, manufacturing and first pass yield calculations are all playing a role as metrics, suitable optimization software tools and processes need to be implemented. Without such solutions, improving manufacturing yield becomes a labor-intensive task that is often set aside.

What is made possible by production optimization software?

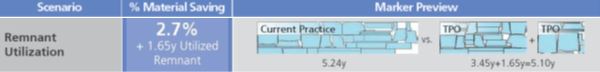

Remnant utilization

Manufacturers employ a variety of ways of dealing with remnants, including returning them to a shelf for future use, recuts (which can often lead to their eventually being discarded), or discarding them immediately.

In just one fabric cutting example (see diagram below), a single set requiring 5.24 yards of material to cut could be nested over multiple rolls to make sure shorter rolls could be used. With actual stock taken into account, a direct saving of 2.7% of material was delivered, indirectly ‘saving’ remnant waste. When remnants are methodically used in production, the manufacturing yield climbs to 87.3% and represents a true figure.

Multi-order nesting

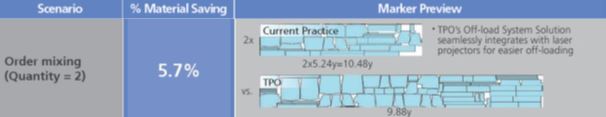

Nesting software often means that two orders requiring the same material are cut from two different rolls. By combining different orders in a single nest using the dynamic production plans, production optimization software can deliver impressive levels of efficiency. Integrating the orders platform with the cutting platform enables manufacturers to mix two orders on the same nest to use material in the most efficient way possible, delivering 5.7% material savings (see diagram below). Additionally, there are further savings to be made in labor and set-up times because only one roll is being pulled from stock, loaded, and cut.

Even in cases where there are mixing constraints that prevent orders being combined into a single nest, seamless integration with the ERP and CAD systems allows two orders to be placed ‘back-to-back’ on a single roll. For the example above, production optimization software still delivers material savings of 4.4%, alongside the significant time and labor efficiencies.

Measuring and monitoring the right metrics produces new efficiencies

When the wrong metrics are measured, potential savings in the nesting and cutting process can be overlooked. Best-in-class manufacturers concerned with continuous improvement and costing are increasingly measuring overall manufacturing yield rather than product level nesting yield, in order to identify and address previously hidden costs.