At Plataine, we’ve got a simple view on AI-based optimization solutions: they bring radical benefits to manufacturers. Of course, we’re a provider of such AI solutions, so you could be forgiven for thinking, “Well, they would say that, wouldn’t they.” That’s why we’ve introduced a free trial package for our Time Sensitive Material (TSM) Manager solution, allowing you to see for yourself how easily you can setup and start using our TSM solution.

Over the years, we’ve found that there are many customers who want to try new technologies but feel that it is too time consuming while factory staff are always extremely busy with production. They feel that they wish to improve processes but do not have the time to evaluate new stuff.

That’s why we’ve taken the big step to develop an easy-to-use application for time sensitive material management, plus offering a free “test drive”. For customers that take up the offer, it’s a no-strings way of actually experiencing all the benefits of our solution. We are consistently finding that, once customers have tried Plataine, they don’t go back.

Try & Buy (or don’t buy – it’s up to you!)

Our Try & Buy package is a 30-day, no-strings-attached free trial of our Time Sensitive Material Manager solution. It provides a sneak peek into the future of digital manufacturing with zero risk, zero downtime, and zero cost; and it delivers real, quantifiable benefits on your shop floor. If, at the end of the 30-days, you decide you don’t want it, then no problem: you can back out, with no commitment on your side.

Option to add RFID sensors

While some customers are fine with barcode scans, others seek for higher levels of automation. To accommodate this need we added an option to add an RFID kit to the mix that comes with a charge. Although this option is not mandatory in order to experience the power of the TSM solution it does provide a window to experience the level of automation achieved with RFID.

So, what are the benefits?

A great recent example of one of our customers who started out with our free trial, and opted to keep it, was Light & Strong. Light & Strong is a technology leader in the composite parts sector. The company is focused on creating advanced composite components that offer cutting edge capabilities to demanding clients in defense and civil aviation. Light & Strong was already renowned for high levels of productivity and efficiency but, when it was recently acquired by India’s Lohia Group, it led to a fresh focus on how its internal production processes could be improved still further using the latest AI and IIoT (industrial internet of things) technologies. Additionally, the global labor shortage meant that any new automation solutions were highly desirable as they would free up staff for more important tasks.

They conducted a thorough search of the market, looking for a comprehensive AI and IIoT partner with experience at working in the aerospace sector. Once they had found Plataine, they opted for the Try & Buy package. Deployment was quick and simple, and caused zero downtime. At Light & Strong, the Plataine solution automatically manages time sensitive, freezer-stored composite raw material. Material is received, tagged with an RFID sensor, and logged in the system. It is then assigned to production in the smartest possible way, making sure to use up material short rolls and remnants, as well as material with a limited exposure time left (ETL), wherever possible.

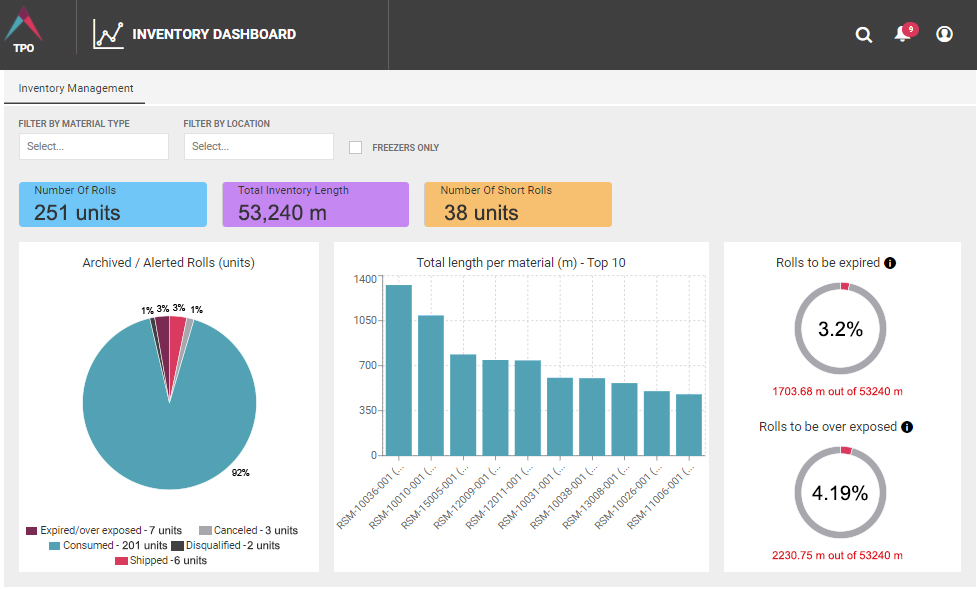

Plataine’s technology provides total visibility across all inventory; it tracks and reports material properties in real-time, such as remaining shelf-life and ETL. Constant tracking and recording of the process results in a live map enables the Digital Assistants to identify upcoming problems, allowing them to be solved before they occur, by providing the operators with alerts and real-time recommendations. Meanwhile, the Digital Thread, a full record of every aspect of an asset’s lifecycle from raw material to end product, means any kits impacted by materials later found to be defective can easily be identified and tracked down, while also ensuring the factory is always audit-ready. Easy planning and ordering is enabled by an inventory dashboard, and fully cloud-based software means the product is available anywhere, anytime, and does not need installing locally.

At Light & Strong, the benefits were immediate and clear, and included:

- A significant reduction in material waste

- The elimination of human error

- The freeing up of valuable workers for higher value tasks

- Full visibility of upcoming production problems

- Improved quality control

In fact, these benefits were so apparent that it wasn’t just management that wanted to keep the solution: the factory floor staff were equally impressed, and they insisted that it should be implemented permanently.

To conclude, in today’s fast moving environment you cannot afford to manage hundreds and thousands of inventory items using Excel or paper – it simply does not make any sense.

You now have the opportunity to try how a cloud solution can improve your operations – it’s easy and will not consume any of your time – you simply login and start using it!

To learn more, read the full Light & Strong case study, or, contact us to continue the conversation about how our technology could help you with our digital transformation experts.