They say that necessity is the mother of invention, and when it comes to new technologies or Industry 4.0 solutions in specific, that is absolutely true. Evolution stems from real pain and in our manufacturing case, the pain is driven by volatile market demand for better and faster manufacturing procedures; margins that continuously decrease; and fierce competition between companies that no organization can win without the help of smart technologies. At the same time, the world is currently grappling with the human and economic crisis unravelling due to the pandemic. It’s becoming increasingly clear that we will come out the other end significantly different since COVID19 is, clearly, a game-changing event. It is obvious that now more than ever, implementing industry 4.0 tools is crucial for the shorter and longer-run.

Industry 4.0 is gaining domination:

According to a PWC survey, 91% of industrial companies are already investing in forming digital factories, with clear goals and ROI expectations for the next 5 years. Companies understand that this is a marathon rather than a sprint and are willing to put in the time and work more than ever before.

Since no journey is ever without a few hurdles, we’ve gathered the main challenges that Aerospace and Automotive composites manufacturers today face as they begin to (or wish to) embrace Industry 4.0 technologies. These challenges can deter some manufacturing businesses from adopting these tools, which might cause them to fall seriously behind their competition. To help companies avoid this outcome, we’ve also added some tips from world-renowned experts to help overcome these challenges in the best way possible.

Challenge #1: Using legacy and outdated systems

As we’ve written in the past, solutions that allow seamless integration into data-systems are the key to success. Today’s most advanced manufacturers are already leaning on multiple legacy data-systems, from Excel sheets to ERP systems, MES systems or other tools. They are therefore concerned by adding more systems that are not flexible enough in terms of integration. They do not want to spend a fortune and endless resources on setting up new tools, and they don’t want to be constantly busy in coordinating or closing data gaps between systems.

Well, contrary to a common misbelief, there’s no need to replace the company’s entire equipment and infrastructure in order to implement the necessary Industry 4.0 solutions. and in many cases, there’s no need to sweat over the integration. Many of today’s IIoT solutions offer an easier path towards innovation and enable companies to make far smaller adjustments and add intelligence, sensors, and automation on top of the existing structure.

Many leading manufacturers overcome this challenge by adding new technology layers on top of legacy systems that continue working as before. This simplifies the industry’s 4.0 onboarding.

They use new layers of technology to:

- Seamlessly integrate with all legacy layers and import needed data and functionalities to be under a single framework

- Add Artificial Intelligence capabilities such as predictions, alerts, and recommendations.

- Automate manual processes, such as updating systems with data or creating reports.

Challenge #2: Understanding the ROI of Industry 4.0 solutions

It can be tricky to estimate the ROI of Industry 4.0 solutions (although we’ve developed a pretty solid method), which is more than enough to scare some companies away. Manufacturers that consider embarking on such an in-depth journey want to know AHEAD of time what’s in it for them and ensure that the investment is worthwhile, which is understandable.

In order to truly answer this question, it’s not enough to present numbers regarding the possible future developments in any dedicated field. Instead, we must translate terms like AI and automation into efficiency, productivity and alike. This is especially relevant now, when cutting costs has become increasingly important as we return to production and get back to routine in the midst of the Covid-19 pandemic.

We are often doing just that for any new manufacturing business we onboard, while also taking into consideration the company’s specific production-floor characteristics and profitability improvement goals. There is a need to shift from PoC (Proof of Concept) to PoV (Proof of Value). In other words, during piloting the technology, assess not only that the technology works but mainly the business value and improvements it brings.

Challenge #3: Deciding on the practicalities

The Industry 4.0 revolution really is transforming the manufacturing field (as well as many others), which makes it equally exciting and overwhelming.

It’s not always clear how to take the first practical steps. Should new solutions replace existing systems, or be added on top? What budget to allocate? What executives to appoint for the project? Also, which areas to focus on first: should it be sensitive time material management and saving? Perhaps tool and inventory management? Quality control and process optimization?

How to measure success, by steps? What to expect in terms of the results?

Yes, a lot of questions.

The possibilities are endless, but you do have to start somewhere, which makes determining your next step a real challenge. This holds many manufacturers back.

I have two thoughts here.

First, start with defining the main business problem you wish to solve. We’ve managed to form a system that lets manufacturers estimate exactly how smart their factory currently is and which aspect should be improved. Businesses that measure their agility and automation levels, for instance, might learn that given the company’s levels of manual labor, these are the solutions they should focus on right now, whereas their time-to-market technologies still serve them quite nicely. This initial exploration stage is important and when conducted with the right focus can lead to smart conclusions.

Use this guide to estimate how smart your manufacturing business really is and to decide what areas should be optimized first:

Second, and as for how to manage an Industry 4.0 onboarding project (in terms of costs, project management, expectations, success measures, training and alike) I would highly recommend leaning on the technology vendor you’ve selected.

When we help our customers onboard Industry 4.0 technologies (Plataine software in this case) we help them manage the entire project, from the strategy to the most granular implementation. Our experts help them create the right project steps, support them by filling infrastructure gaps, training the employees, estimating direct and indirect costs, defining success measures, calculating ROI and alike.

Read this article in order to make sure that you onboard a technology (and a service provider) that fits your needs.

Challenge #4: Utilizing data

There’s no doubt that IIoT technologies drive companies to collect data like never before, but when it comes to actually putting said data to use, that’s where things get a little blurry.

Aerospace and Automotive composite manufacturers are challenged by the amount of data that can be collected, and they just don’t know how to leverage it for their business goals. Understanding how to leverage specific data for YOUR specific KPIs is critical in onboarding the right industry 4.0 tools that best match your interests.

When such a level of understanding is very challenging, then onboarding the right technologies becomes a challenge as well.

Manufacturers should know how to analyze and utilize data wisely, or else the wrong conclusions might be reached.

In today’s reality, many manufacturers end up gathering a massive amount of data, only to sit and stare at endless information with no clue as to how it should be interpreted.

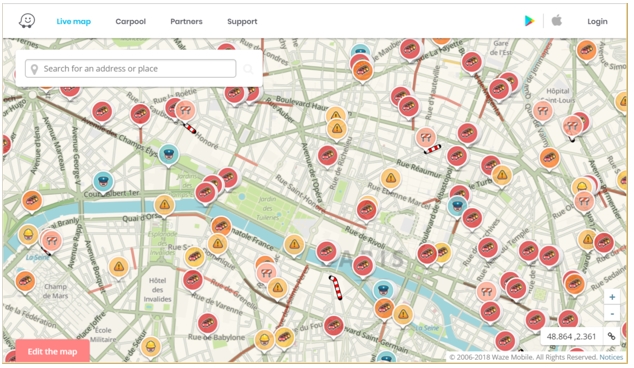

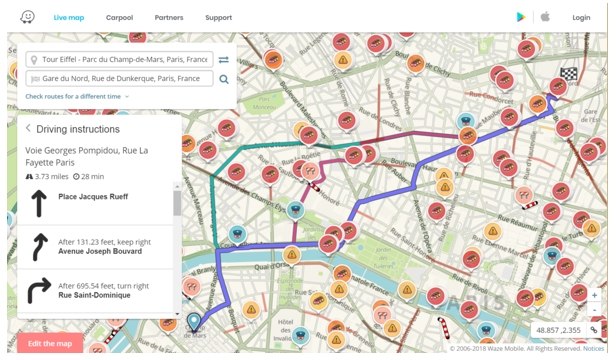

Here’s an example I love using. Take a look at this Waze navigation dashboard image (it not the app we’re using, this dashboard is on their website):

It provides a lot of information, but can a driver use it while driving from point A to point B?

As the human ability to both predefine the importance of all available contextual data and calculate the implications of the data is limited, many manufacturers moved to work with technologies that overcome the challenge and take the load, by:

- Automating data gathering, hence the manufacturers need not worry anymore about resources or energy that are involved in gathering so much data.

- Generating actionable insights based on that data and by leveraging AI. Let the machines run complex calculations, predict future scenarios based on historical data, simulate different decisions and their consequences and send us, eventually, simple and clear recommendations as for what to do:

“use that tagged material that will expire soon”, “don’t put that work station on this task”, “switch these tools as the first one needs maintenance”, “don’t use this machine currently- it gets too hot” …

And that’s what you need to expect the machines to hand over to you:

Let the machines do what they do well…

Challenge #5: Too much of a good thing…

We’ve mentioned that there are endless possibilities in IIoT, but there are also countless offerings and promises popping up in every corner. Aeropsace and composites manufacturers find it challenging to decide which vendor to collaborate with based on their current state and future goals, which experts to consult with, and how to find their golden nugget in the sea of technologies and professionals. That’s not to say that many of the options out there aren’t good, but what works for one manufacturing business will not fit another. This means that companies must first assess their business needs, and only then examine the solutions and vendors abilities to address them.. To get started, here are 5 concrete use cases that can be managed only with a certain level of AI, and can help you get inspired.

Summary

In today’s reality, as we get back to routine, manufacturers will now need to create an out of box tactical recovery plan that will set their near future. History shows that the strongest players came out of crisis even stronger. It’s rather obvious that the above list doesn’t cover every single challenge that manufacturers face as they embark on the Industry 4.0 journey. The ever-changing nature and fast pace of IIoT technologies also means that this list of challenges will continue to evolve over time. Topics like data ownership and knowledge preservation, for instance, are becoming crucial nowadays. This article, which covers some of the biggest, most important issues for manufacturers today, is mainly focused on sending one clear message: every challenge has a solution, and you need to research and implement it, step by step.