Blog

Don't miss the latest updates

A step-by-step journey: How this Aerospace composites factory optimizes production with AI & IIoT

Under pressure from global material and workforce shortages, the rising prices of raw materials, and the growth in demand, Aerospace composites factories today acknowledge the need for digital acceleration. They have started to adopt new smart-factory technologies in order to become more agile and effective, increase profitability, boost productivity and cut costs.

What do hyper automation and industry 4.0 manufacturing optimization implementation look like? This article reveals the step-by-step journey of an Aerospace composites manufacturer as it leveraged IIoT and AI to cut costs and boost profitability.

10 Questions Discrete Manufacturers Must Ask Before Choosing an Industrial IoT Solution for Their Connected Factory

While the decision to implement an IIoT / connected factory / Industry 4.0 solution is a no brainer, choosing and onboarding the right IIoT provider and the right solution remains a big challenge.

There’s no better time than now to put together a digital transformation plan and start looking for the right supplier.

While the decision to implement an IIoT / connected factory / Industry 4.0 (or alike) solution is a no brainer, choosing and onboarding the right IIoT provider and the right solution remains a big challenge.

AI based hyper automation in manufacturing – here’s how it’s done in practice

Lean manufacturing is as relevant today as it ever was, but it is evolving. Meanwhile, digitalization is one of the most talked about trends in modern manufacturing, but in its goals – minimizing waste and maximizing productivity – it could be said to be an extension of Lean. In fact, at Plataine, we think that digitalizing your production line is only likely to be successful if all production line operators and managers think in terms of the Lean goals of waste minimization and productivity maximization. Before considering deploying a digital manufacturing solution, it’s vital to plan in advance. While the best solutions can be deployed with zero downtime, the process will still incur a significant cost both financially and in terms of training staff to use the new system. To lay the groundwork, you need to accurately calculate the ROI of your investment, and ensure that all stakeholders have bought into the concept. With full internal buy-in, the financial benefits are significant.

So how does it help my bottom line?

Aerospace Composites: 6 Big Questions To Ask Before Onboarding Time Sensitive Material Management Software

The number of elements on a factory floor that might cause a particular efficiency or quality problem make it nearly impossible to pick out a single tool, process or condition as the culprit.

Due to supply chain disruptions (post-Covid), factories experience material shortage while logistics and procurement managers testify that material orders that used to be fulfilled in weeks now take months.

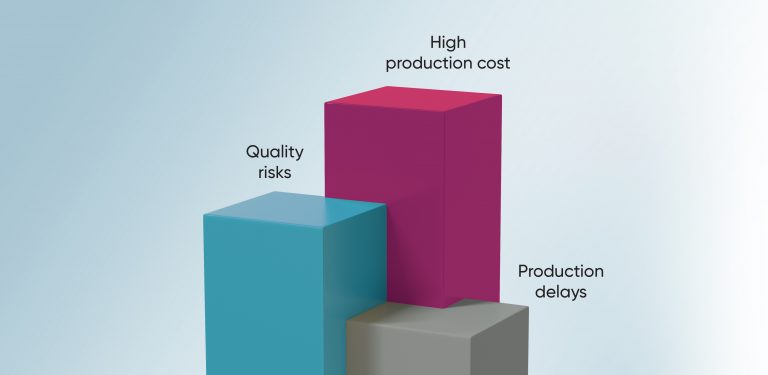

Many manufacturers are turning to Industry 4.0 software with AI-based algorithms, that’s tailor-made for aerospace composites, in order to deal with specific challenges.

Successfully reaching the Factory of the Future level with Industry 4.0 technologies, requires software to solve specific challenges that are part of the day to day work life in the Aerospace composites industry.

Here are the 6 key questions aerospace composites manufacturers should ask when selecting the optimal solution.

Managing Time Sensitive Material: once you’ve tried Cloud AI, you can’t go back

At Plataine, we’ve got a simple view on AI-based optimization solutions: they bring radical benefits to manufacturers. Of course, we’re a provider of such AI solutions, so you could be forgiven for thinking, “Well, they would say that, wouldn’t they.” That’s why we’ve introduced a free trial package for our Time Sensitive Material (TSM) Manager solution, allowing you to see for yourself how easily you can setup and start using our TSM solution.

We’ve taken the big step to develop an easy-to-use application for time sensitive material management, plus offering a free “test drive”. For customers that take up the offer, it’s a no-strings way of actually experiencing all the benefits of our solution. We are consistently finding that, once customers have tried Plataine, they don’t go back.

This Aerospace composites manufacturer added an AI layer on top of MES. Here’s what happened

The Light & Strong production team was constantly searching for new levers of process automation in order to reduce material waste, improve quality control, and offer real-time visibility across production lines so issues could be tackled before they arose.

Due to the global labor shortage, the company was keen to automate any processes that could be automated to free up factory staff for higher value tasks.

During this time, the company’s management decided to further explore AI-based IIoT technologies and the implementation of advanced Industry 4.0 layers on top of its MES solution.

Read the blog to find out more.

Top Industry 4.0 trends – 2022 SME global manufacturing survey highlights

Today, digital transformation plays an integral role in any manufacturing business strategy, to translate investments into tangible results at the enterprise level. The past 2 years accelerated fundamental changes to how manufacturers interact with legacy enterprise systems (such as MES) to maintain business continuity, improve agility and increase responsiveness to market fluctuations.

According to this 2022 SME unique industry survey, factory floors are managing to properly collect sufficient data and to use advanced analytics methods to improve operational efficiency.

This article sheds light over some of the trends revealed in the report.

How an AI layer on top of MES is a game-changer: Reducing operational costs in Aerospace composites by 15%

MES solved and still solves crucial challenges such as managing complex data and taking advantage of data analytics.

But, nonetheless, these systems were initially built for another era and to be honest did not manage to completely eliminate the paperwork. We witness a lot of paper documentation that travels together with work orders or inventory transactions.

Today, the aerospace composite industry’s challenges have changed and technology capacities have evolved tremendously…

2022 Industry 4.0 trends in the aerospace composites manufacturing sector

Due to the ongoing pandemic recovery, priorities continue to shift towards compensating losses by cutting costs, boosting efficiency, and implementing technologies that will help us to cope with the next crisis and keep resilience. This article will help us gear up for 2022 by focusing on trends that are already rising, around mitigating risks, expanding capabilities, and moving forward into Industry 4.0 and the future of manufacturing.

So, without further ado, what does 2022 hold for aerospace and composites manufacturers?

More With Less: The Dramatic Impact of AI Combined with IIoT on Reducing Manufacturing Operational Costs

To turn technology into revenue, manufacturers must utilize it to both increase income and decrease cost. For advanced manufacturing and complex businesses, such as the Aerospace industry, heavy-machinery and alike, the second part of the equation is particularly important since they struggle with heavy operational costs. Let’s examine how combining AI and IIoT helps them minimize operational costs and increase profit, and which use-cases are worth focusing on.

Adopting Industry 4.0 in Aerospace and Automotive composites manufacturing: 5 challenges & practical tips

In what feels like a minute and an eternity all at the same time, the industry is now busy dealing with a rollercoaster of shifts that impacts everyone in every aspect of our lives in a wide range of fields that include Aerospace, Automotive, Heavy Machinery, and more.

The next paragraphs will examine some of these changes and the main strategies that come along and help manufacturers face today’s challenges, keep the resilience, plan and be prepared for the day after the crisis.

Flawless decision making, from planning to execution? The key role of ‘AI and IIoT’ in Aerospace & Automotive composites manufacturing

Manufacturers working with composites in the aerospace industry face a series of unique and complex challenges. These include the time-sensitive nature of many composite raw materials that require constant monitoring. The Plataine partnership represents a major step forward for Siemens’ aerospace customers, delivering new levels of material savings and manufacturing efficiencies that are tailored specifically to the needs of factories working with composites.