Plataine’s TPO (Total Production Optimization) is a modular suite that offers Industry 4.0 solutions to solve production challenges by utilizing Plataine’s Digital Assistants, delivering alerts & smart recommendations in real-time to digitalize and optimize manufacturing processes.

Dynamic, holistic and real-time: the only Intelligent Automation solutions that optimally decide WHICH production order to run, WHEN, using WHICH raw material, on WHAT machine, while creating the optimal production plans.

Dynamic, holistic and real-time: the only Intelligent Automation solutions that optimally decide WHICH production order to run, WHEN, using WHICH raw material, on WHAT machine, while creating the optimal production plans.

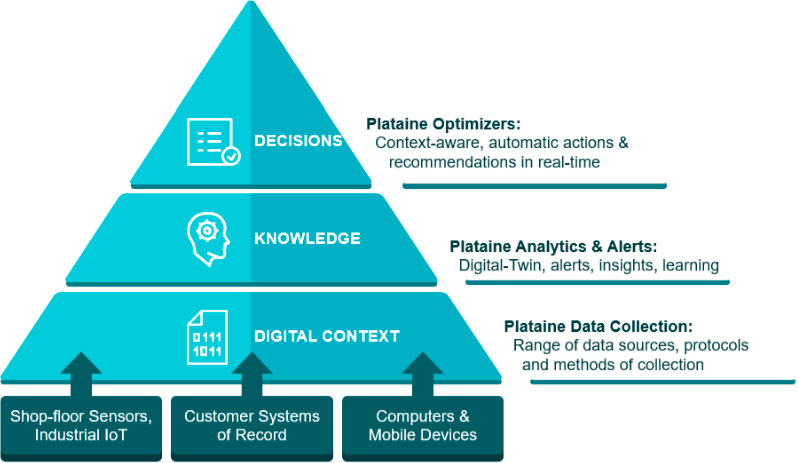

Plataine’s Context Aware Computing solutions leverage the Industrial Internet of Things (IIoT) to create a rich digital context and weave the digital thread for automated and optimized decision making in advanced manufacturing environments. Plataine’s TPO solutions optimally decide which production order to run, when, using which raw material, on what machine, while creating the optimal production plans.

Plataine’s breakthrough Intelligent Automation technology sits between ERP, PLM/CAD, and the shop floor, covering for the “blind spots” of these systems while providing new capabilities at every step of the production process.

Production visibility

Factory throughput increase

Digital traceability

Product cost reduction

Faster time to market

Rework reduction

Over the years, we have developed Plataine’s deployment methodology, enabling quick and efficient implementation.

While many standalone solutions boast their ability to integrate with other systems, Palatine’s holistic suite of applications is built to work together.